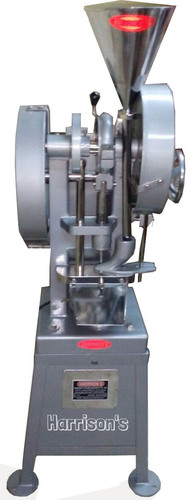

Mini Pulverizer Made of St. Steel

Price 72000 INR/ Piece

Mini Pulverizer Made of St. Steel Specification

- Usage & Applications

- Industrial

- Frequency

- 50 Hertz (HZ)

- Material

- SS

- Computerized

- No

- Control Mode

- Semi-Automatic

- Color

- Silver

- Warranty

- 1 Year

Mini Pulverizer Made of St. Steel Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 30-45 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Mini Pulverizer Made of St. Steel

SS Mini Pulverizer that we bring forth for our clients is designed and developed to reduce the size of the herbs or medicines into powder. Contact parts of these mini pulverizers are manufactured using stainless steel-304 quality. Fitted with a 3 phase motor and a starter, the machines made available by us are known to deliver optimum performance. These mini pulverizers are provided with the provision for affixing mesh of different size.

Specification

|

Color |

Grey |

|

Material |

SS |

|

Size |

Customized |

Efficient Industrial Grinding Solution

The Mini Pulverizer, made of premium stainless steel, offers efficient and reliable grinding for diverse industrial applications. Its semi-automatic control mode balances ease of use and precision, streamlining your material processing workflow. Operating at 50 Hertz, it guarantees consistency and productivity in production environments.

Built to Last with Quality Assurance

Manufactured and supplied in India, this pulverizer is constructed from high-grade stainless steel. The solid build quality and one-year warranty provide peace of mind for industries looking for durable, low-maintenance equipment. Its sleek silver finish also ensures resistance to corrosion and wear.

FAQs of Mini Pulverizer Made of St. Steel:

Q: How does the Mini Pulverizer operate in semi-automatic control mode?

A: The semi-automatic control mode allows users to manage the pulverizing process efficiently, requiring minimal supervision while giving the operator control over loading and discharge. This arrangement streamlines grinding tasks while maintaining high precision.Q: What applications is the Mini Pulverizer suitable for?

A: This pulverizer is designed for industrial purposes and is ideal for grinding, mixing, and reducing the size of various materials used in manufacturing or processing units.Q: When should I consider using this stainless steel pulverizer in my operations?

A: You should use this pulverizer when consistent, high-speed material size reduction is required, especially for bulk industrial processes where reliability and efficiency are crucial.Q: Where is this Mini Pulverizer manufactured and supplied from?

A: The machine is manufactured and supplied within India, ensuring locally sourced components and support for Indian industrial standards.Q: What is the process for pulverizing materials using this machine?

A: Feed the material into the hopper, start the semi-automatic control, and the pulverizer grinds the material using its internal blades. The processed material is then collected for further operations or packaging.Q: How do I benefit from the products stainless steel construction?

A: Stainless steel ensures durability, corrosion resistance, and hygiene, making the pulverizer suitable for use in environments where cleanliness and long service life are required.Q: What warranty support is provided with this Mini Pulverizer?

A: The product comes with a one-year warranty, offering coverage against manufacturing defects and ensuring reliable after-sales support for industrial users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tablet Making Machinery Category

Foil Sealer & Tagger Sealing Machine

Price 5800 INR / Piece

Minimum Order Quantity : 5 Pieces

Color : Red & Black

Computerized : No

Warranty : yes

Tablet Making Machine / Single Punch

Price 84500 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Grey

Computerized : Yes

Control Mode : SemiAutomatic

Warranty : 1

Multi Punch Tablet Making Machine

Price 325000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Blie

Computerized : No

Control Mode : SemiAutomatic

Warranty : 1 Year

Impact Pulverizer

Price 388500 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Silver

Computerized : No

Control Mode : Manual

Warranty : 1 Year

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS