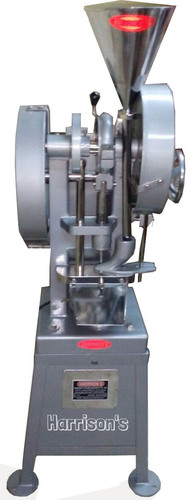

Cyclone Type Pulverizer - GMP Model

Price 148500 INR/ Piece

Cyclone Type Pulverizer - GMP Model Specification

- Usage & Applications

- Industrial

- Frequency

- 50 Hertz (HZ)

- Material

- SS

- Computerized

- No

- Control Mode

- Semi-Automatic

- Color

- Grey

- Warranty

- 1 Year

Cyclone Type Pulverizer - GMP Model Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 30-45 Days

- Main Domestic Market

- All India

About Cyclone Type Pulverizer - GMP Model

Cyclone Type Pulverizer is to reduce the size of the herbs, medicines powder etc. All contact parts of the pulverizer are made of mild steel. The machine is driven by the motor of Three Phase, with starter etc.

Other Details:

- The unit is provided with provision for affixing mesh of different size as per requirement and nature of the material to be pulverized.

- The Pulverizer shall reduce the powder size up to 100 # mesh.

Specification

| Voltage | 220V |

| Phase | Three Phase |

| Material | MS |

| Color | Silver |

Advanced Pulverizing Technology

Engineered for industrial use, the Cyclone Type Pulverizer utilizes a cyclone mechanism that separates particles and increases grinding efficiency. The GMP (Good Manufacturing Practice) design ensures hygienic processing, making it ideal for pharmaceuticals, food, and chemical industries.

Durable Stainless Steel Construction

Constructed from stainless steel, the pulverizer resists corrosion, requires minimal maintenance, and complies with stringent industrial safety standards. Its robust build provides extended operational life, ideal for high-demand environments.

Semi-Automatic Control for Ease

Featuring a semi-automatic control mode, this machine streamlines operation and reduces manual intervention. Operators gain both convenience and control, benefitting from consistent output and straightforward adjustment features.

FAQs of Cyclone Type Pulverizer - GMP Model:

Q: How is the Cyclone Type Pulverizer - GMP Model operated in an industrial setting?

A: The pulverizer operates via a semi-automatic control mode, allowing the user to start and monitor the grinding process with minimal manual input. It is simple to use, making it suitable for industrial environments where efficiency and consistency are essential.Q: What materials can be processed using this pulverizer?

A: This pulverizer is designed to handle a range of industrial materials, including chemical powders, food ingredients, and pharmaceuticals, all while ensuring compliance with GMP standards due to its stainless steel construction.Q: When is it advisable to schedule maintenance for the pulverizer?

A: Routine maintenance is recommended every few months, depending on usage frequency. The stainless steel build minimizes wear, but regular checks help ensure peak performance throughout its 1-year warranty period and beyond.Q: Where can this pulverizer be installed within an industrial facility?

A: Its compact and durable design allows for installation in various industrial settingssuch as manufacturing floors, food processing plants, or chemical production unitswhere quick and hygienic pulverizing is needed.Q: What is the process for pulverizing materials with this machine?

A: Materials are loaded into the feed hopper, where the cyclone mechanism swiftly grinds and separates particles. The stainless steel body maintains cleanliness, while the semi-automatic controls facilitate consistent and efficient operation.Q: How can industrial users benefit from employing this pulverizer?

A: Users gain improved efficiency, hygienic processing, and reliable results. Its semi-automatic operation reduces labor, while the GMP-compliant design meets rigorous quality standards, making it ideal for sensitive industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tablet Making Machinery Category

Dehumidifier Machinery

Price 128500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 YEAR

Computerized : No

Control Mode : SemiAutomatic

Type : Other

Tablet Making Machine / Single Punch

Price 84500 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1

Computerized : Yes

Control Mode : SemiAutomatic

Type : Tablet Pressing Machine

Powder Mass Mixer

Price 92500 INR / Piece

Minimum Order Quantity : 1 , , Piece

Warranty : 1 Year

Computerized : No

Control Mode : SemiAutomatic

Type : Other

Defoiler Machine

Price 68500 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Computerized : No

Control Mode : SemiAutomatic

Type : Tablet Pressing Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS