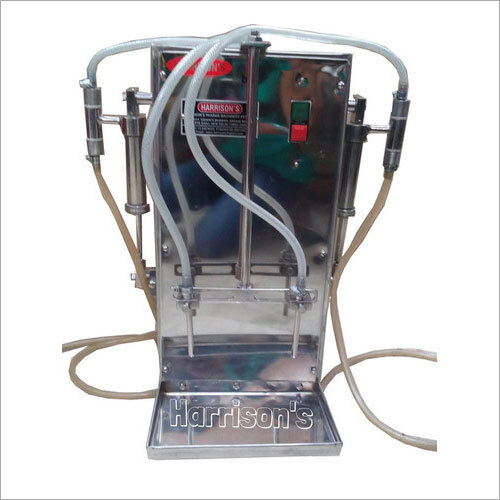

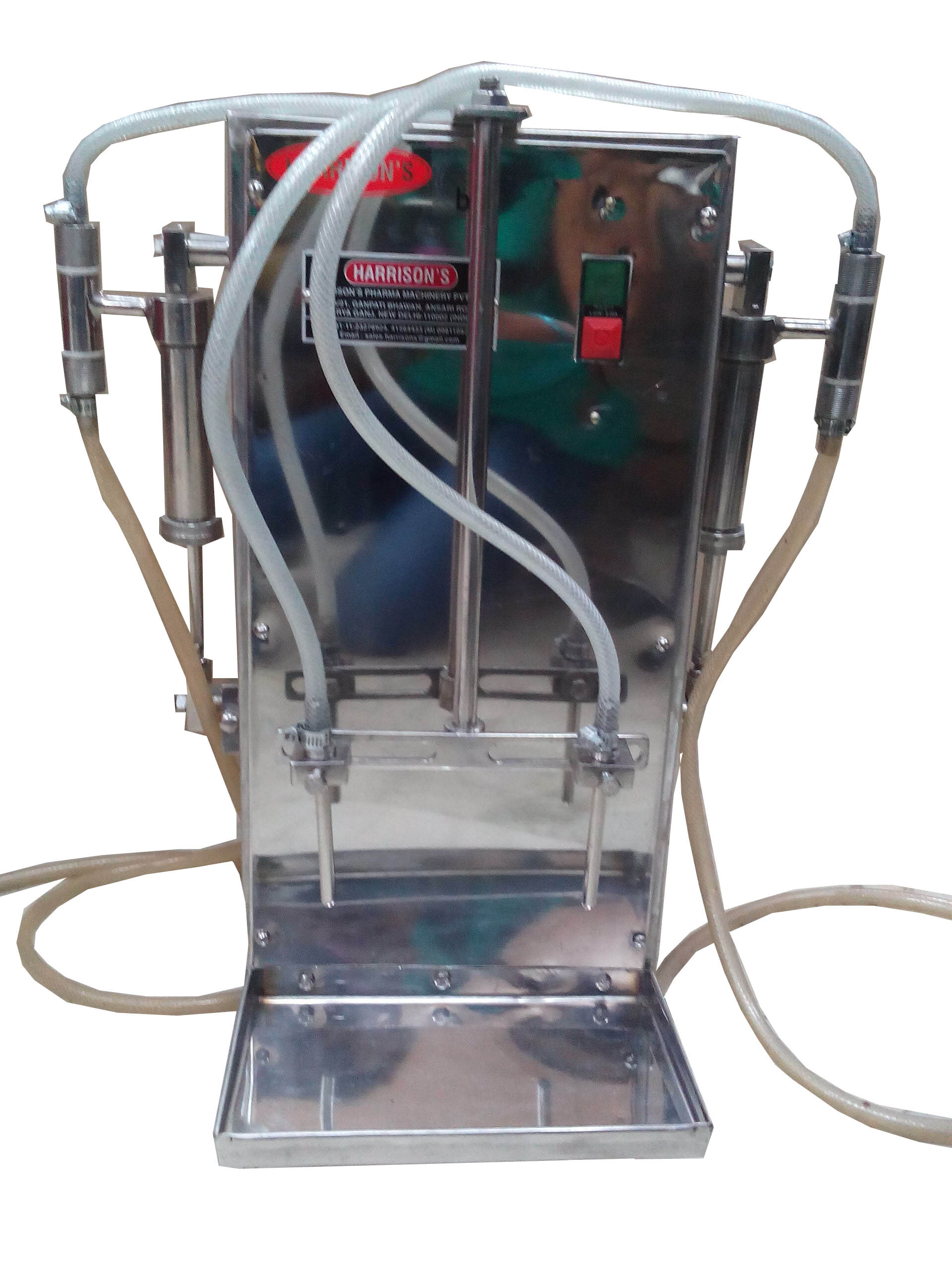

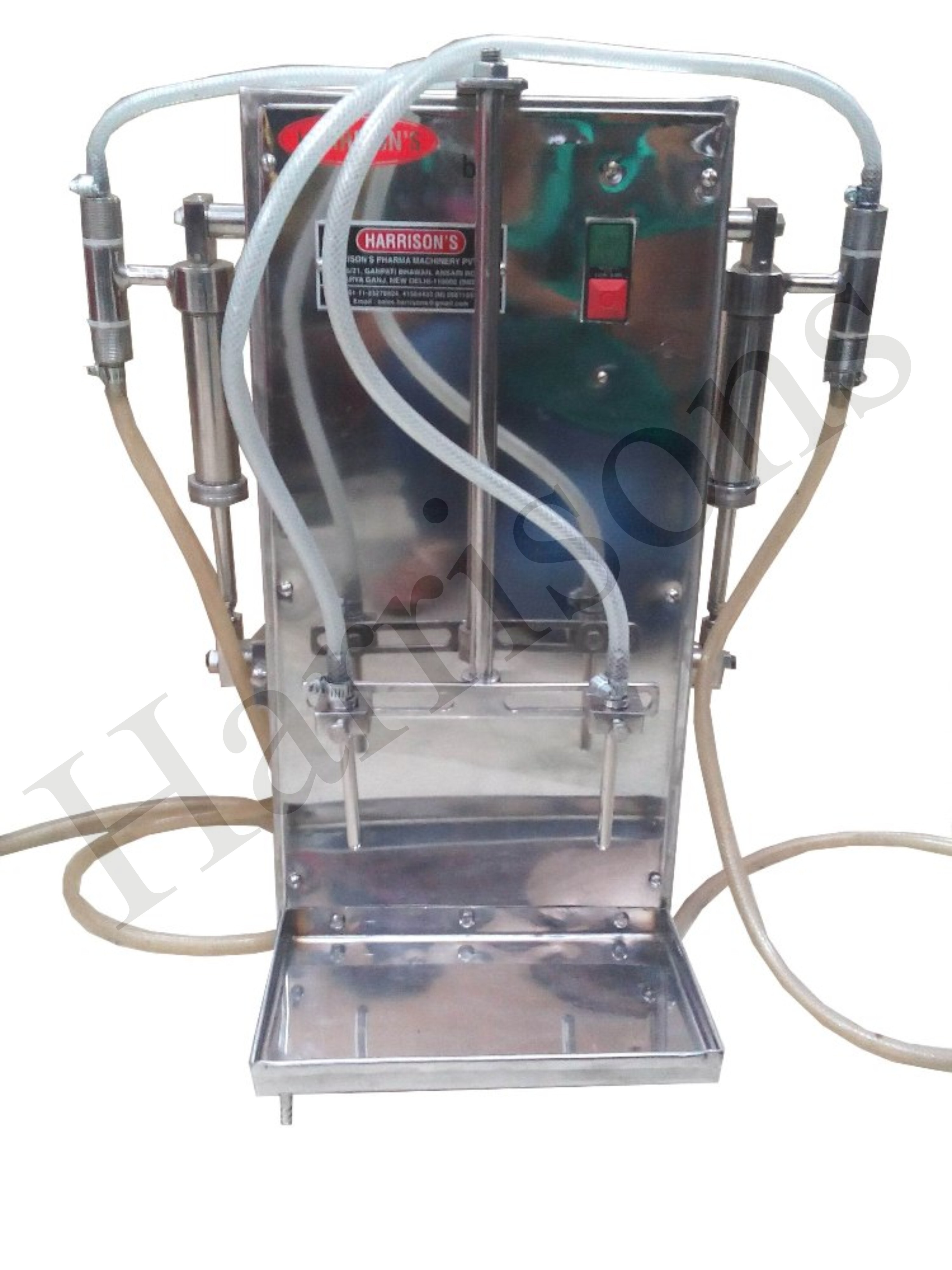

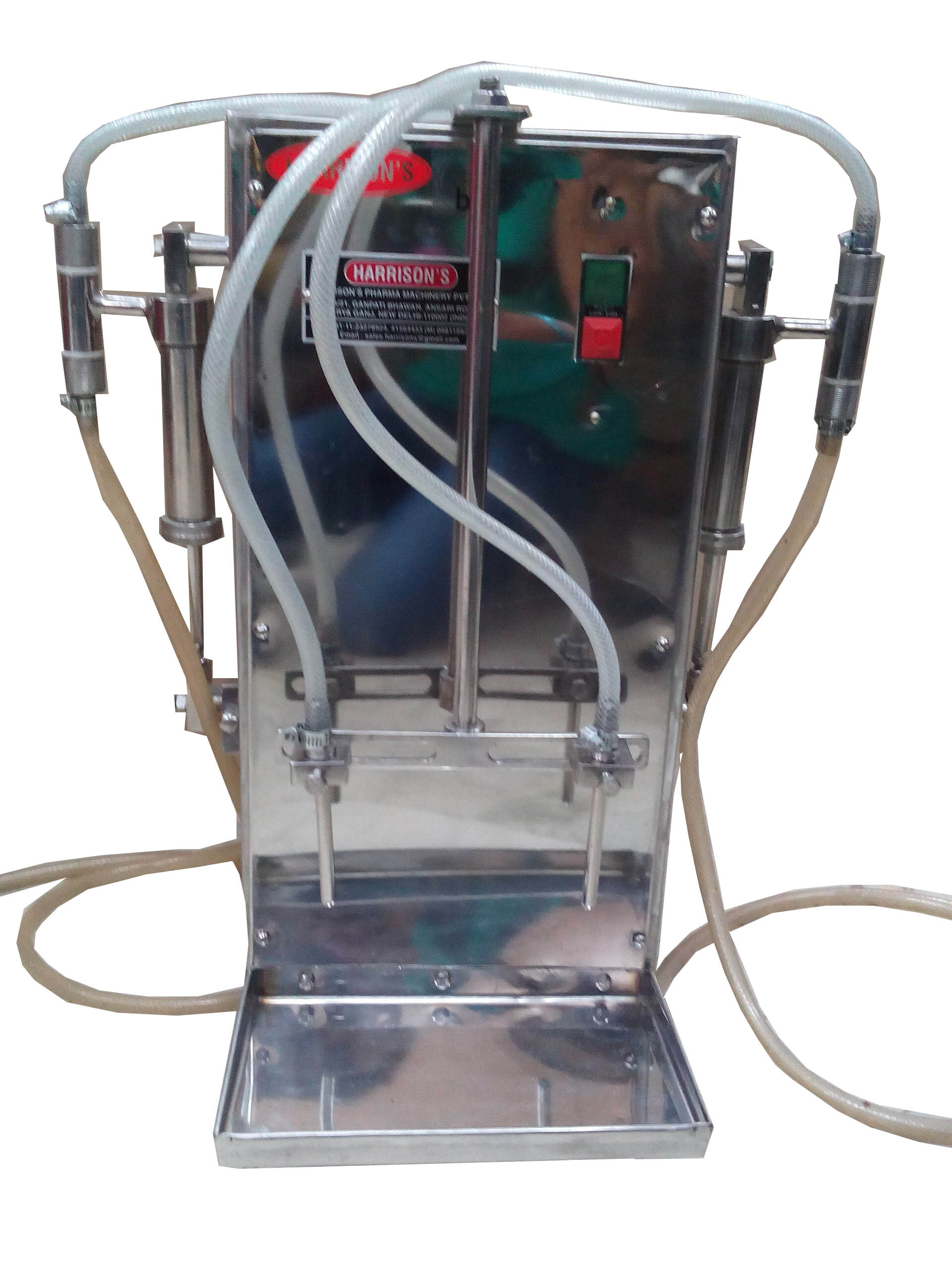

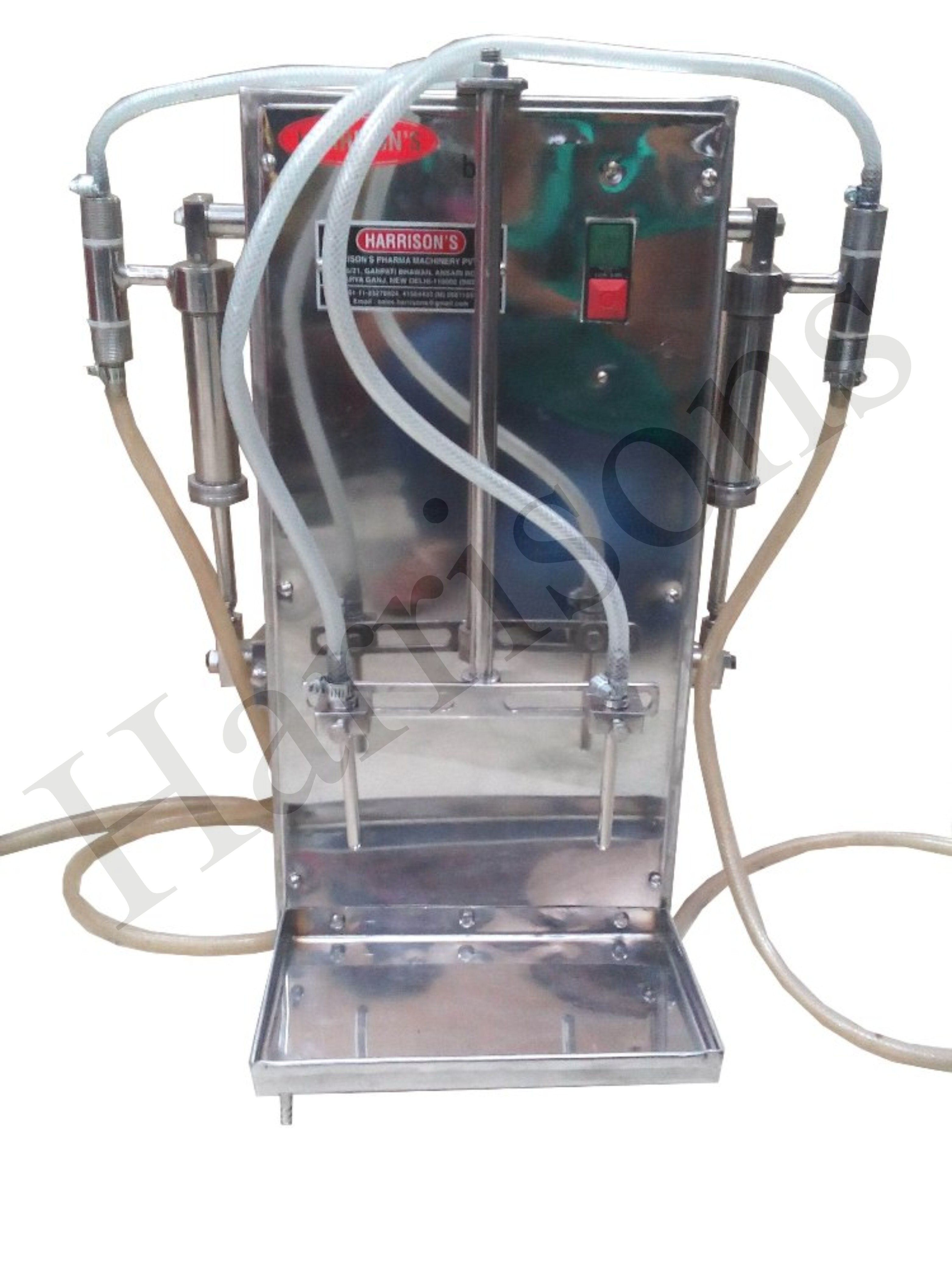

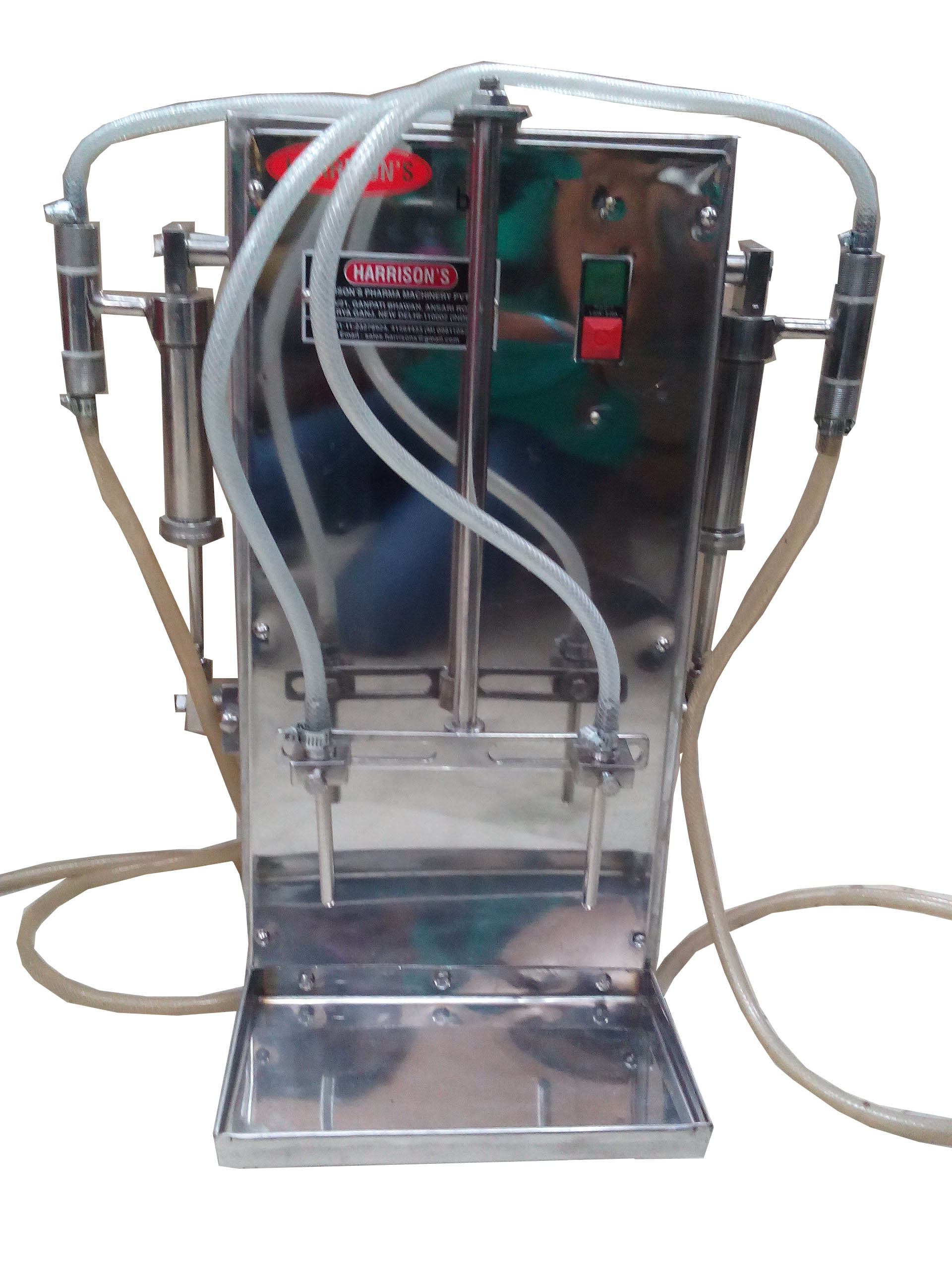

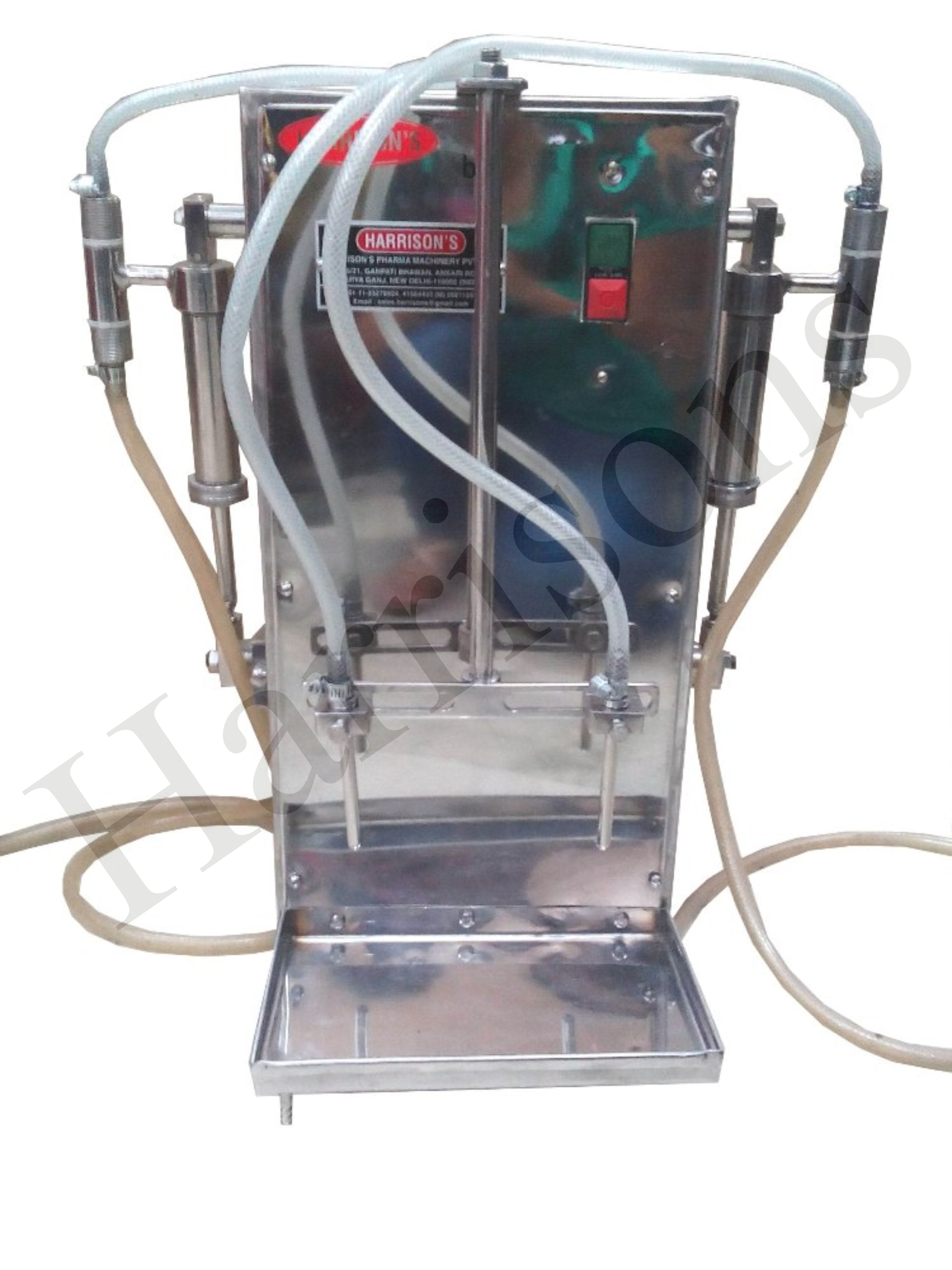

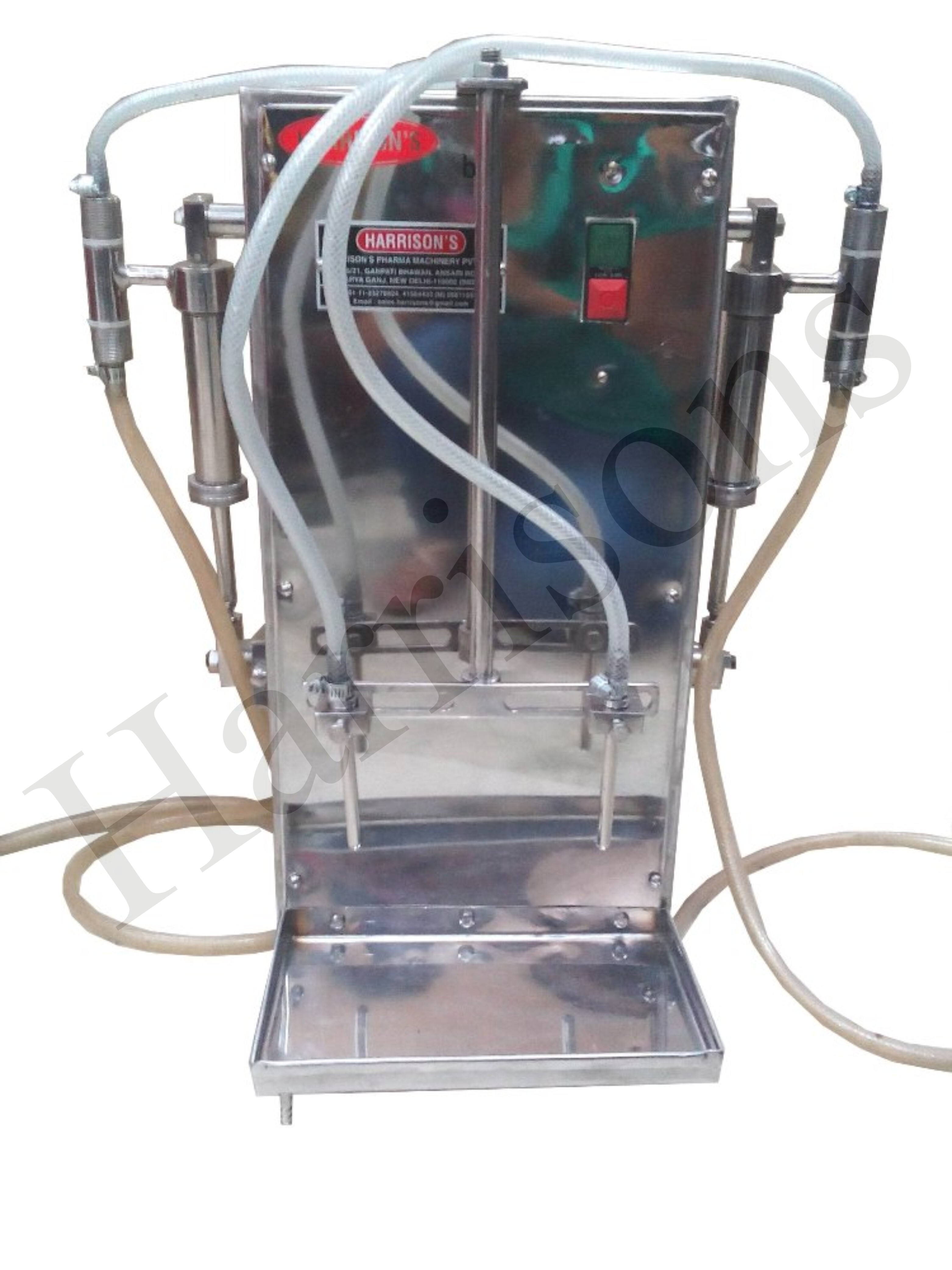

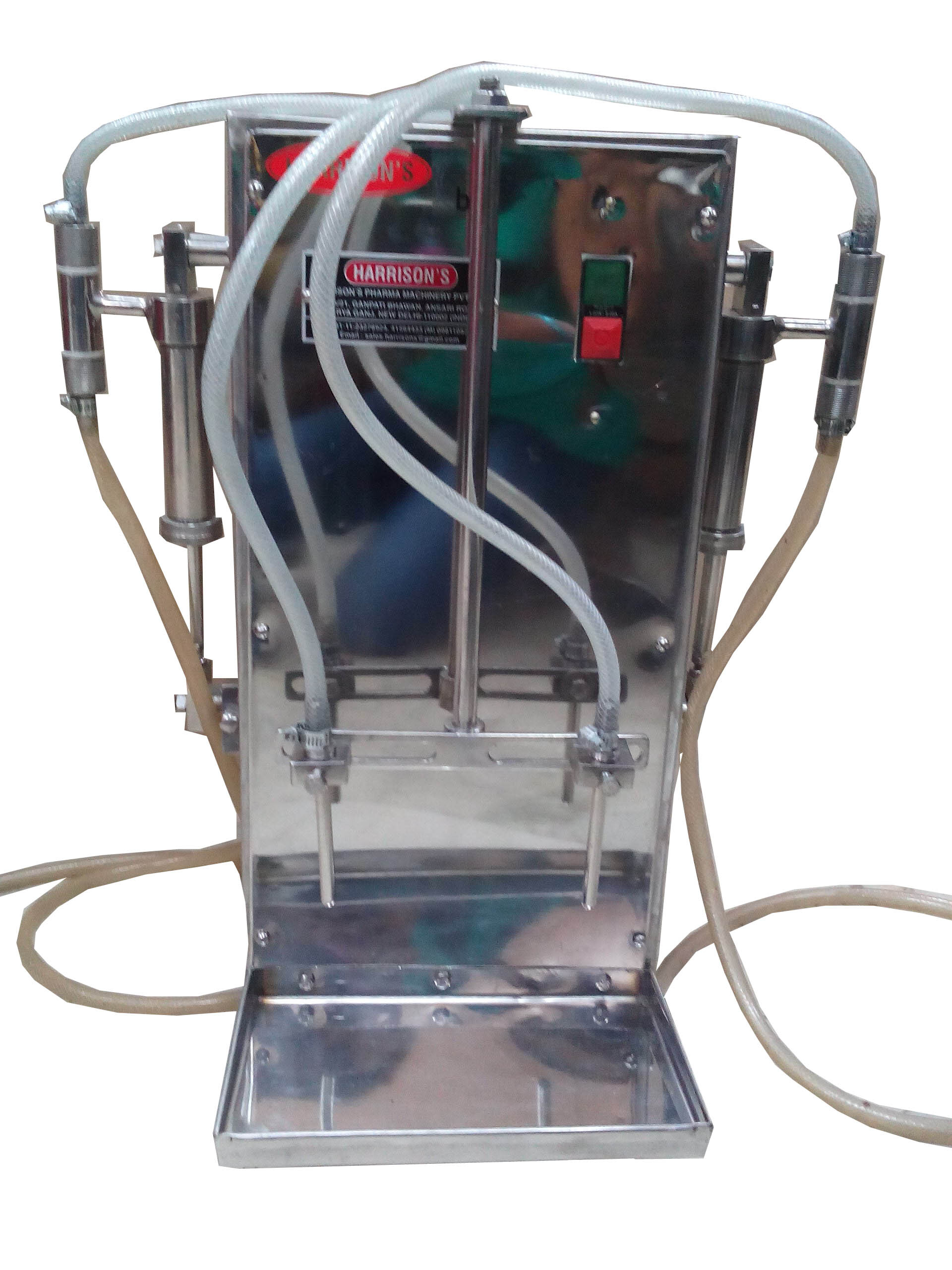

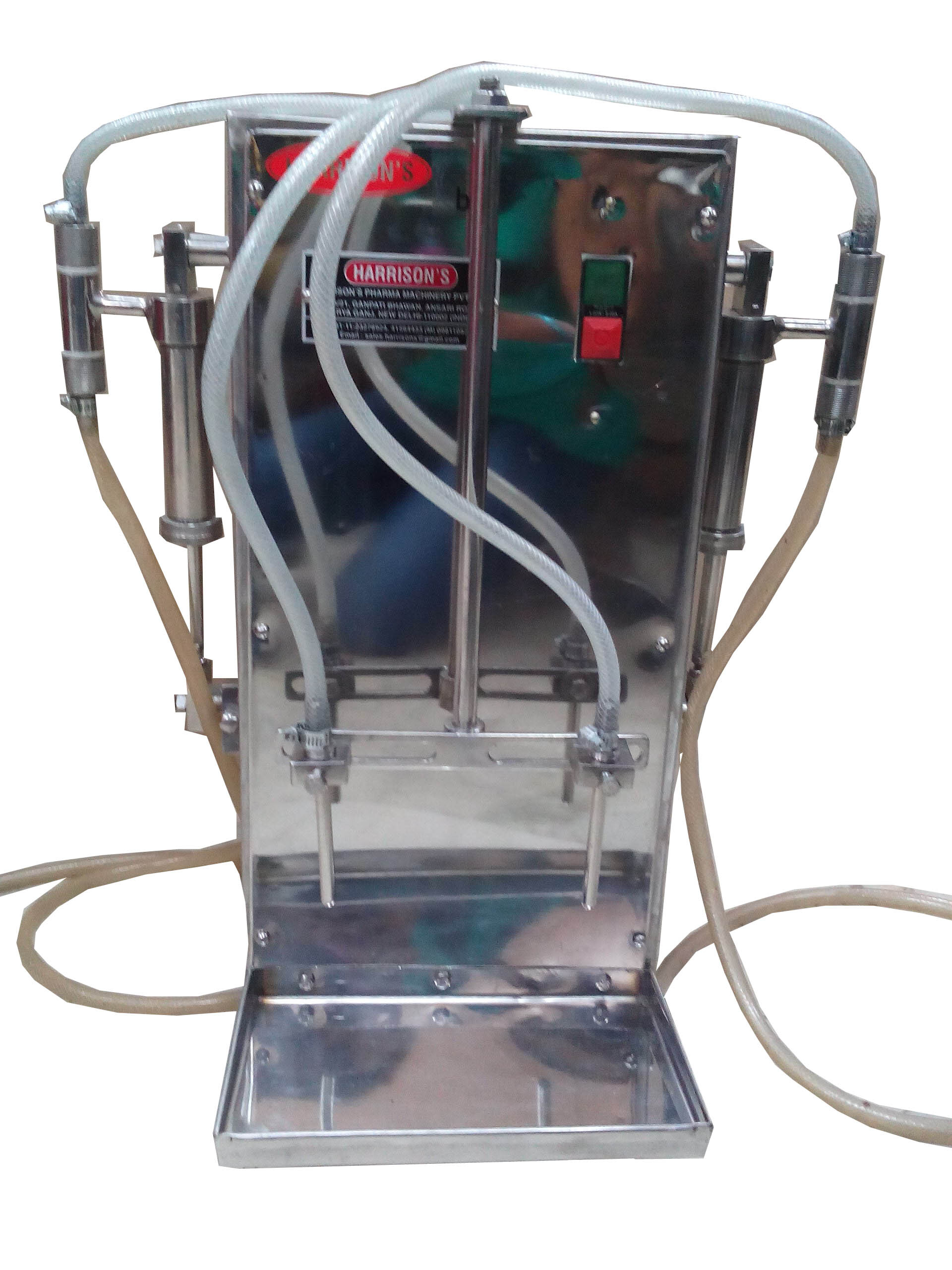

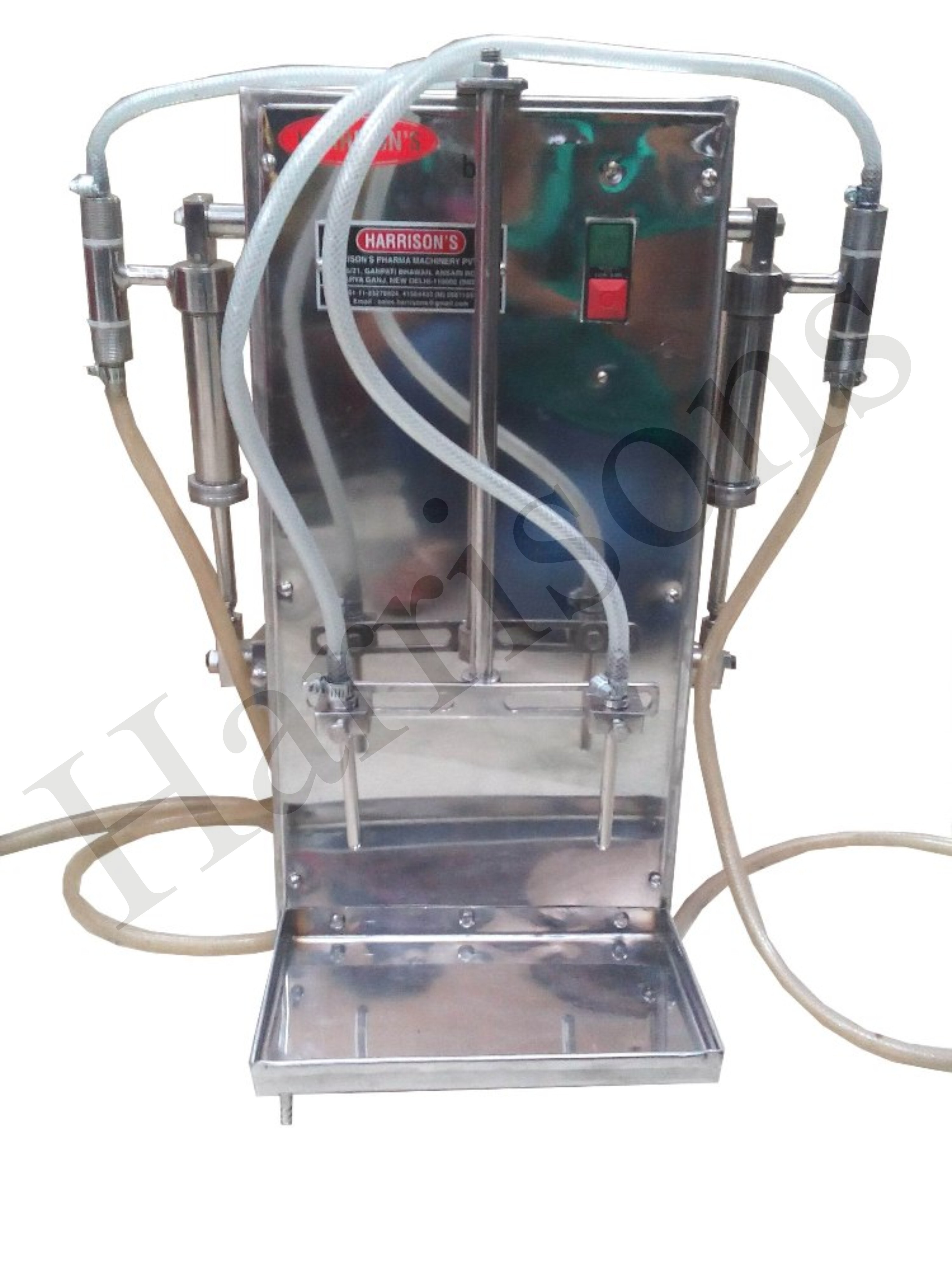

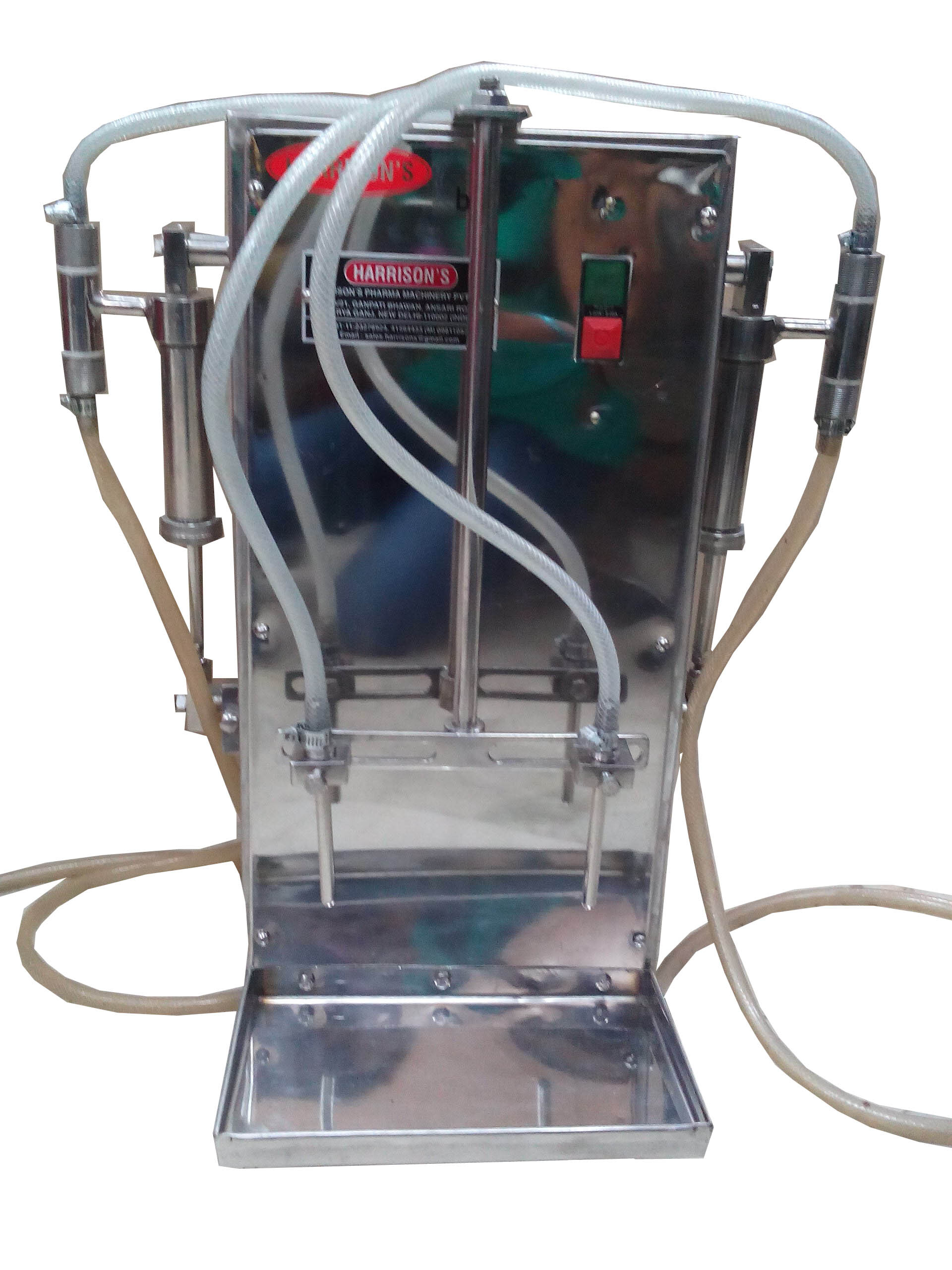

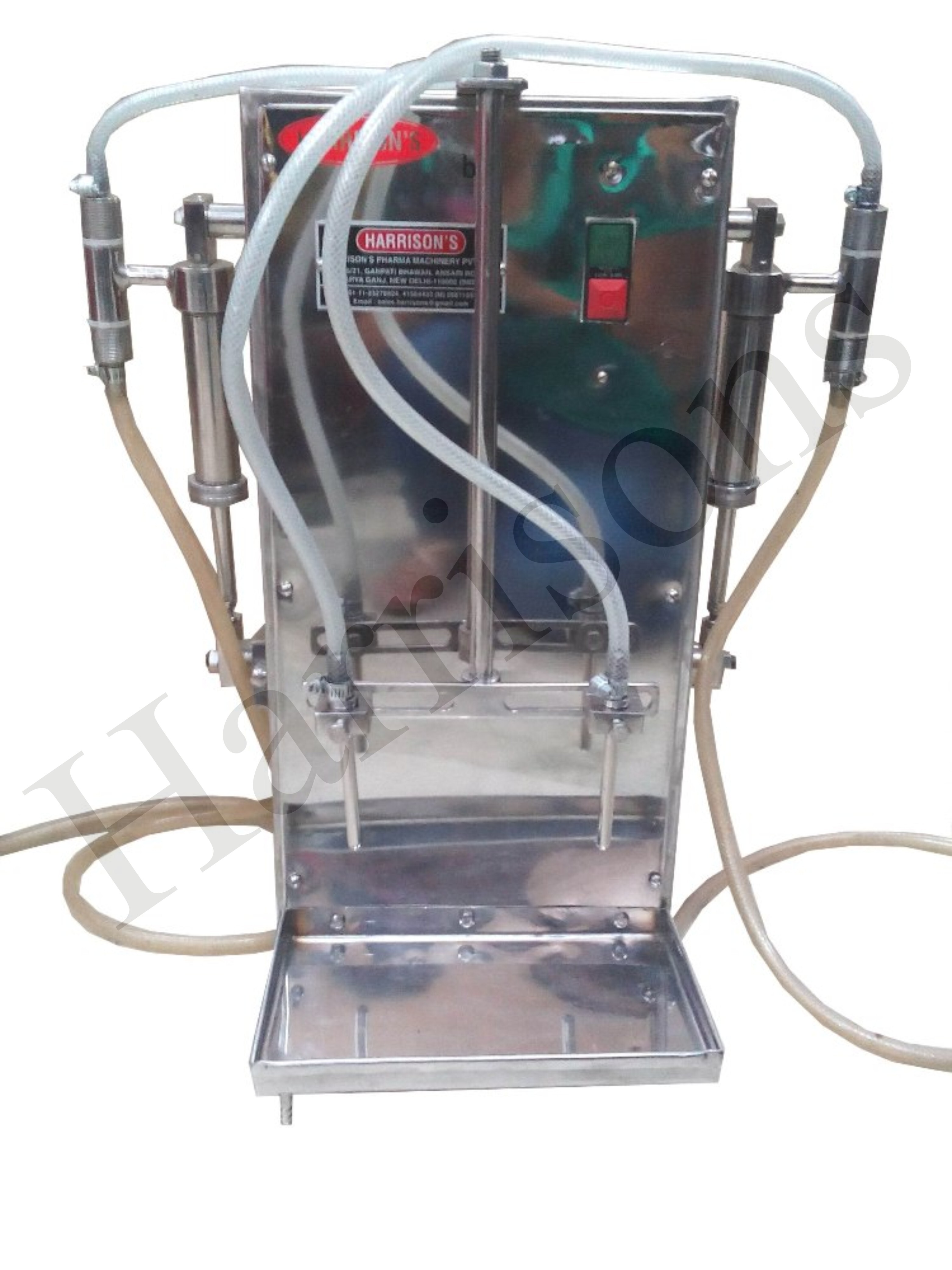

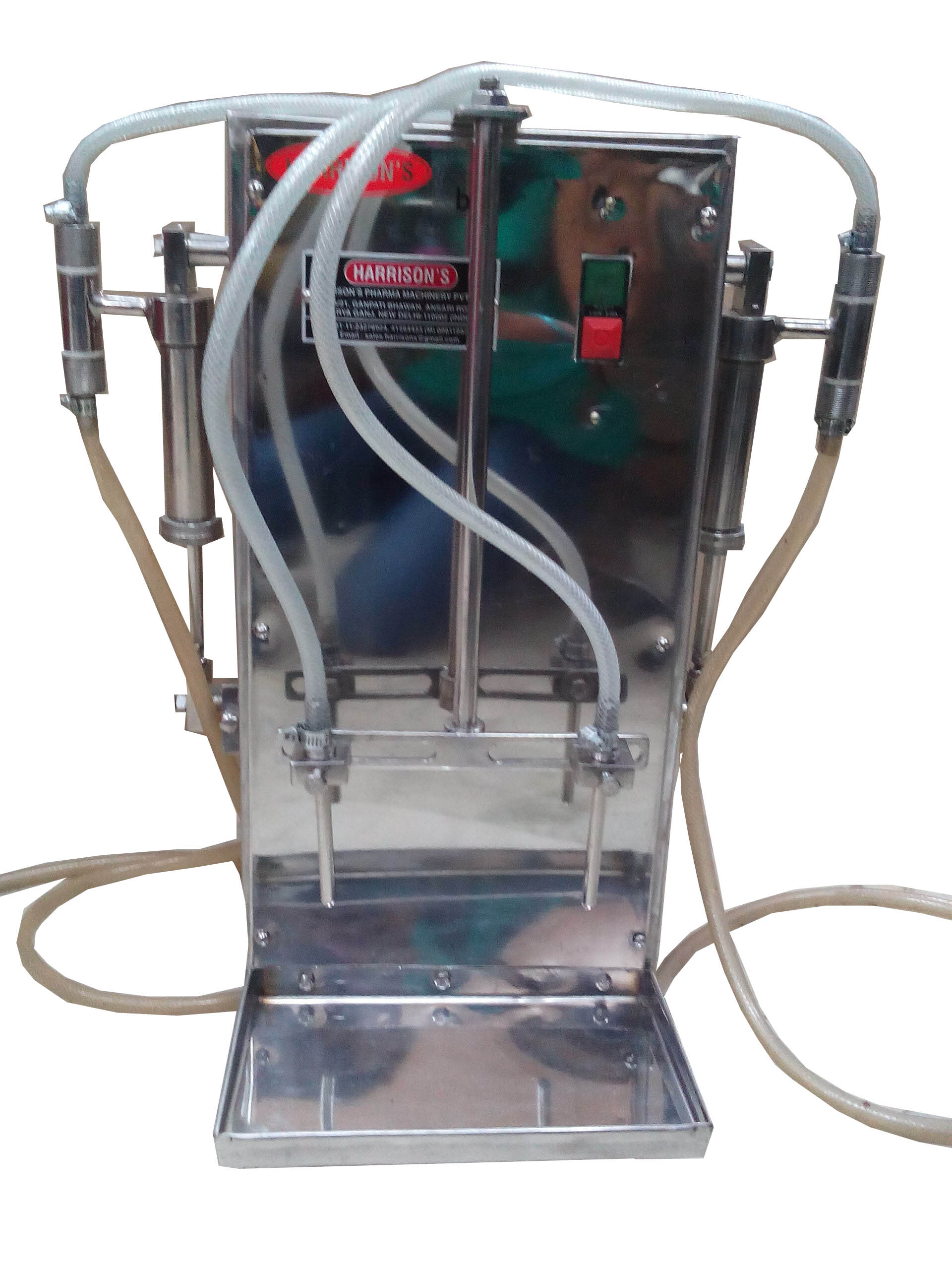

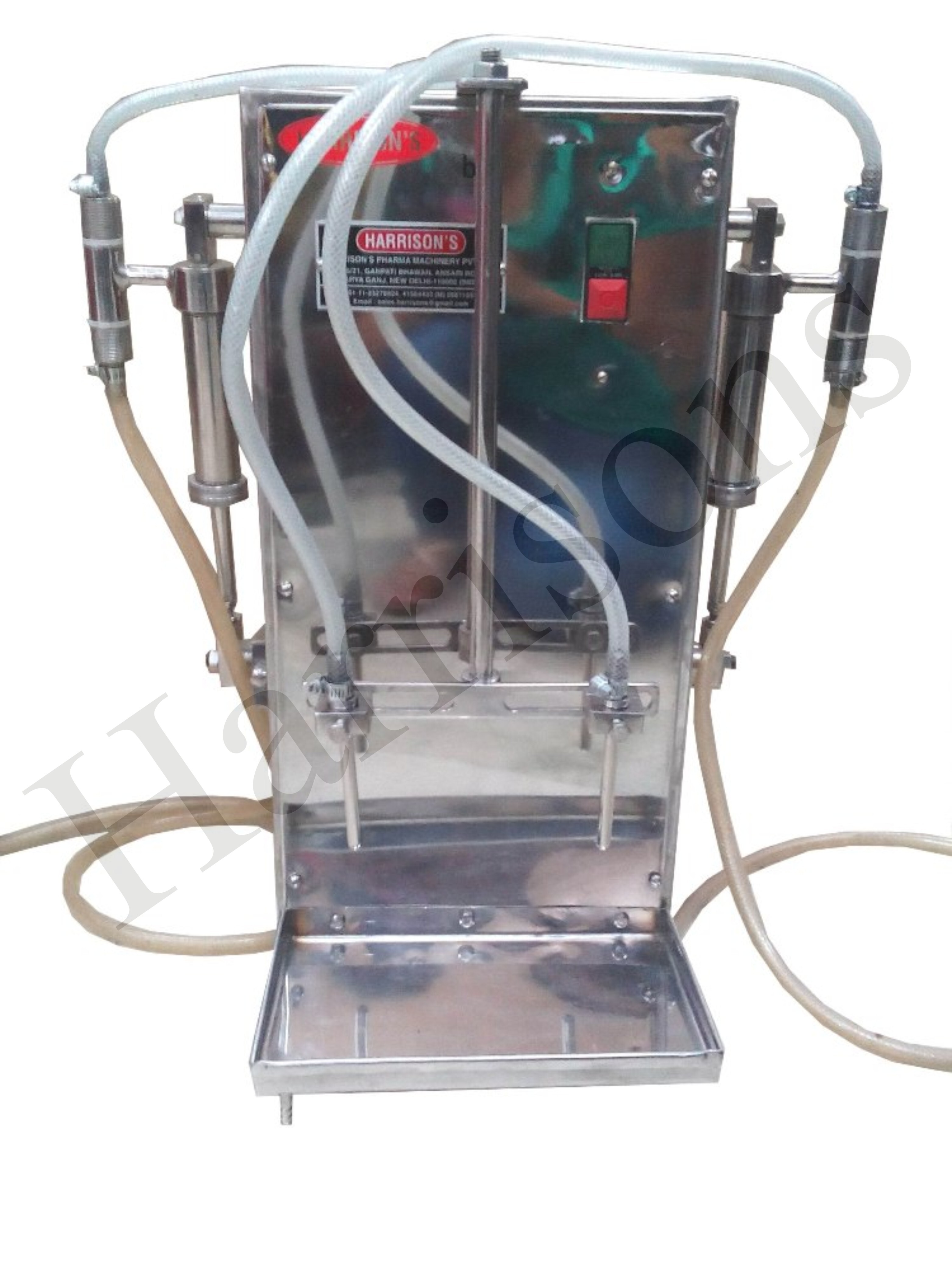

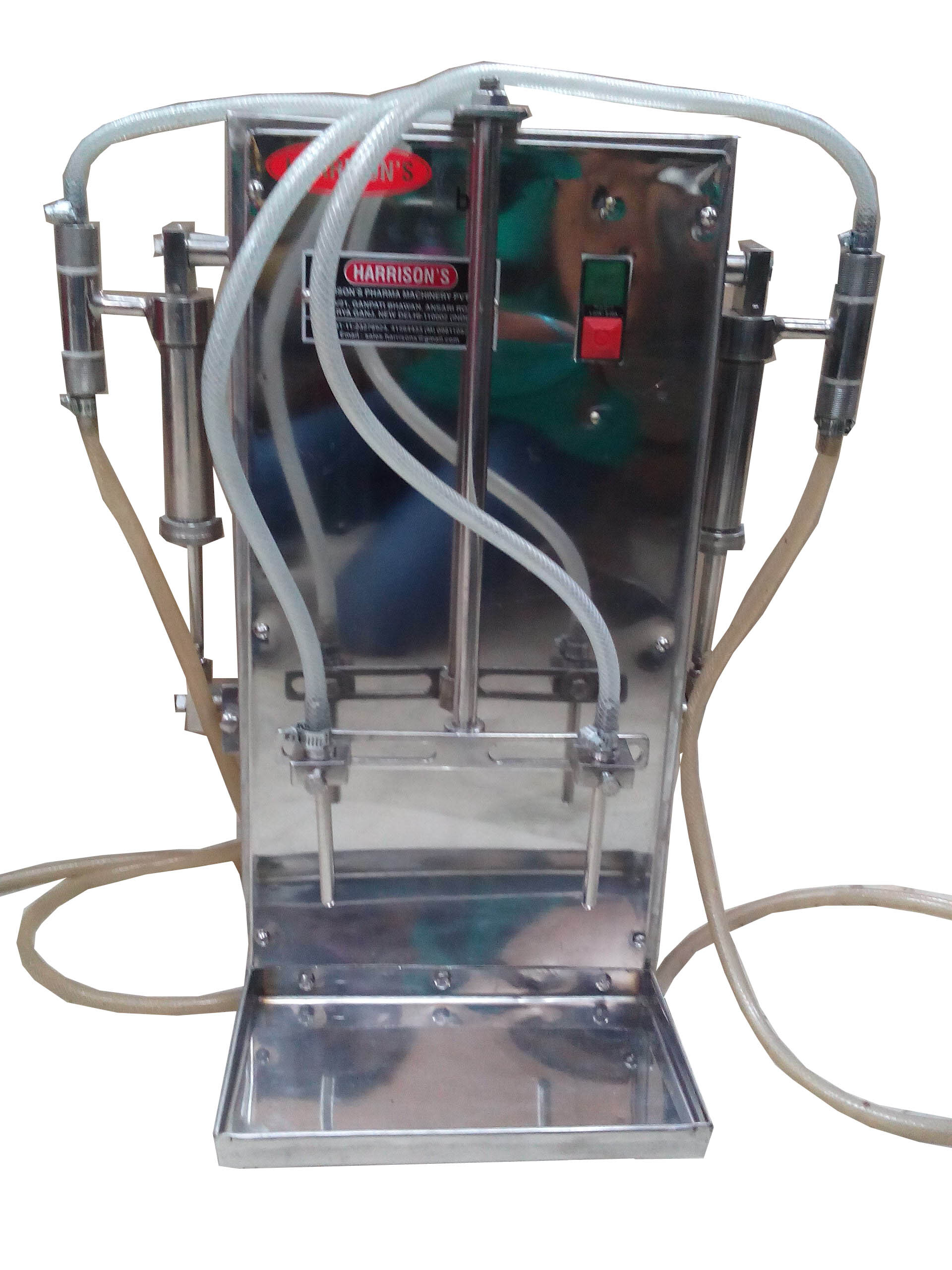

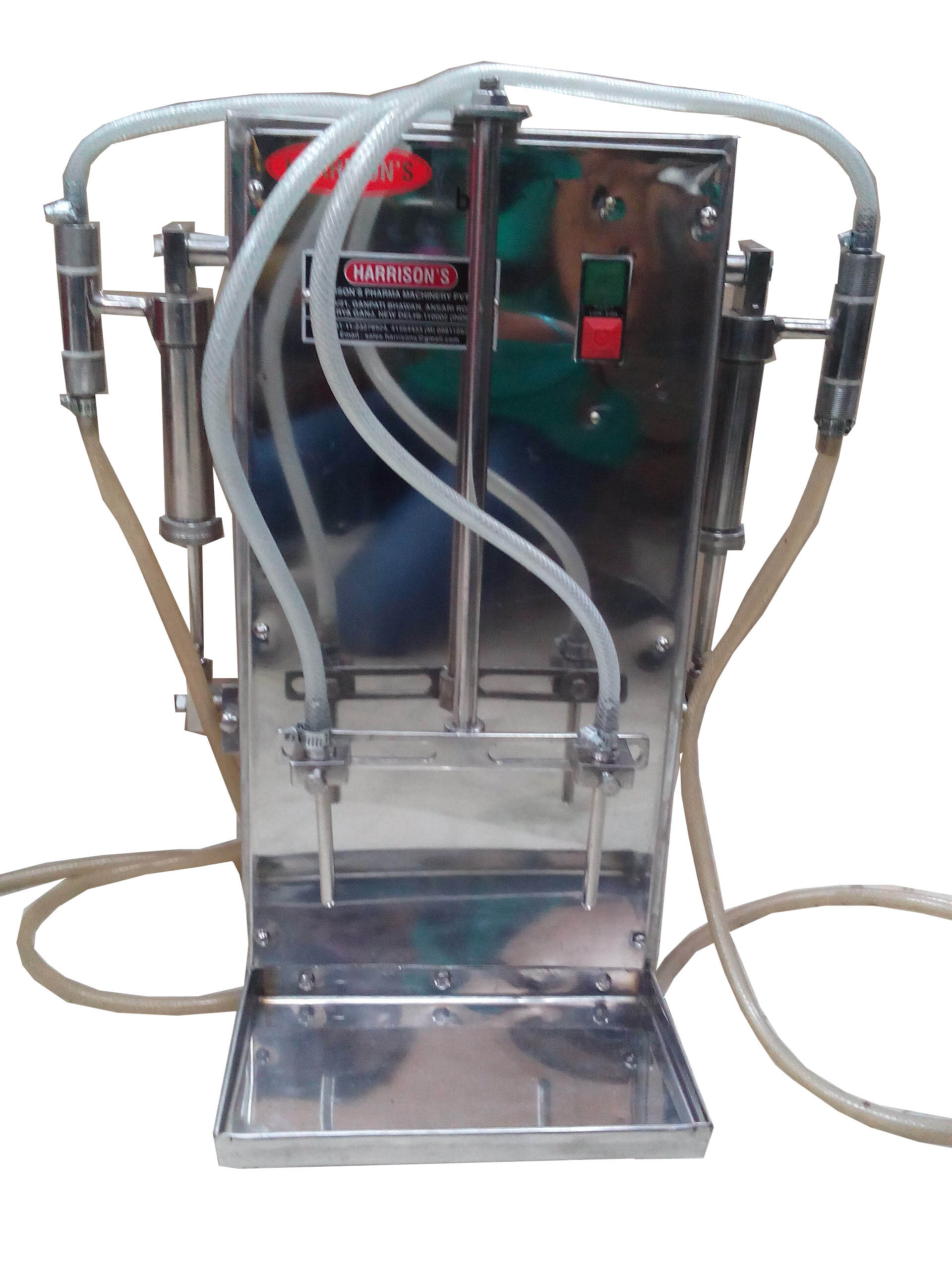

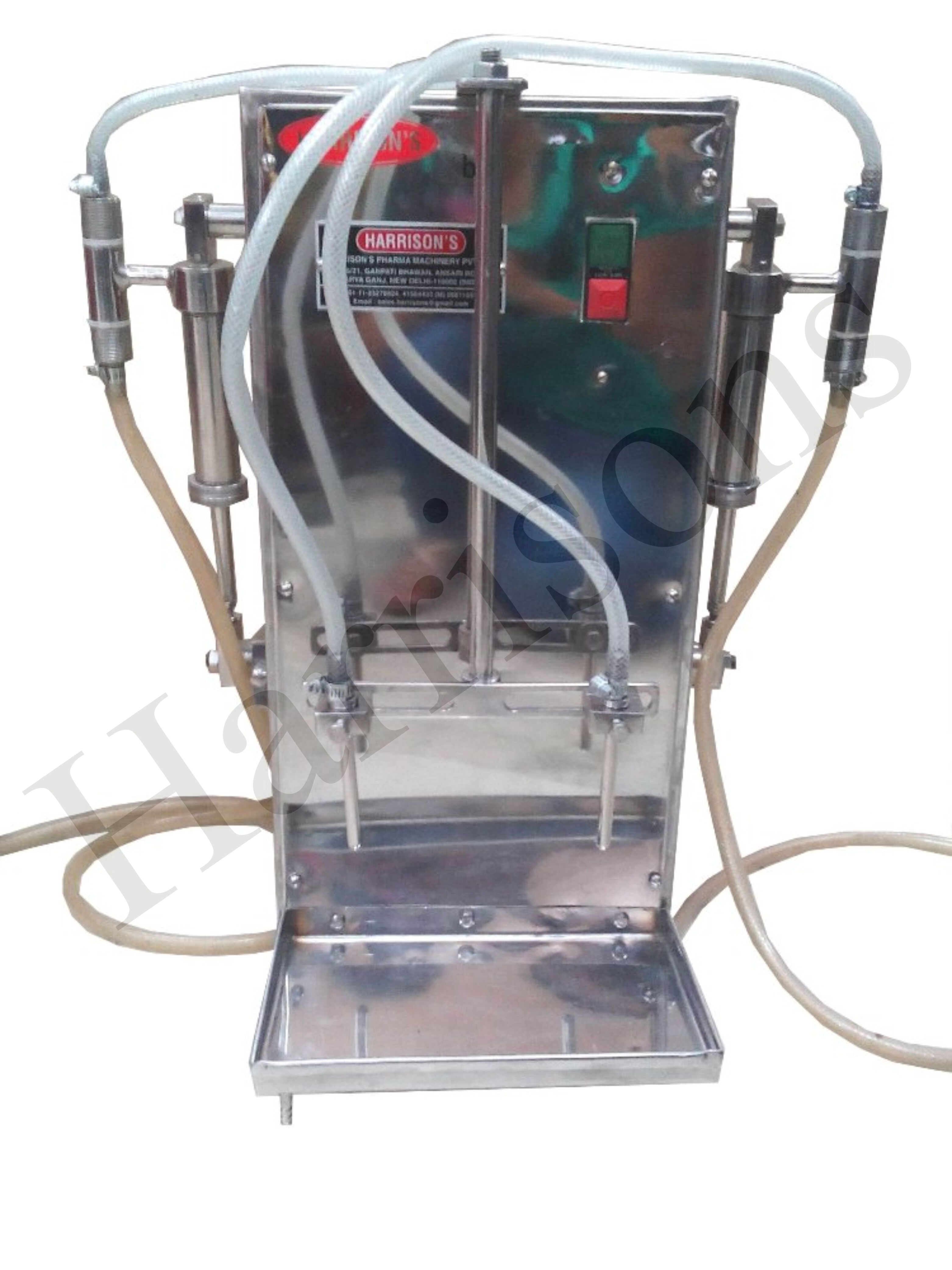

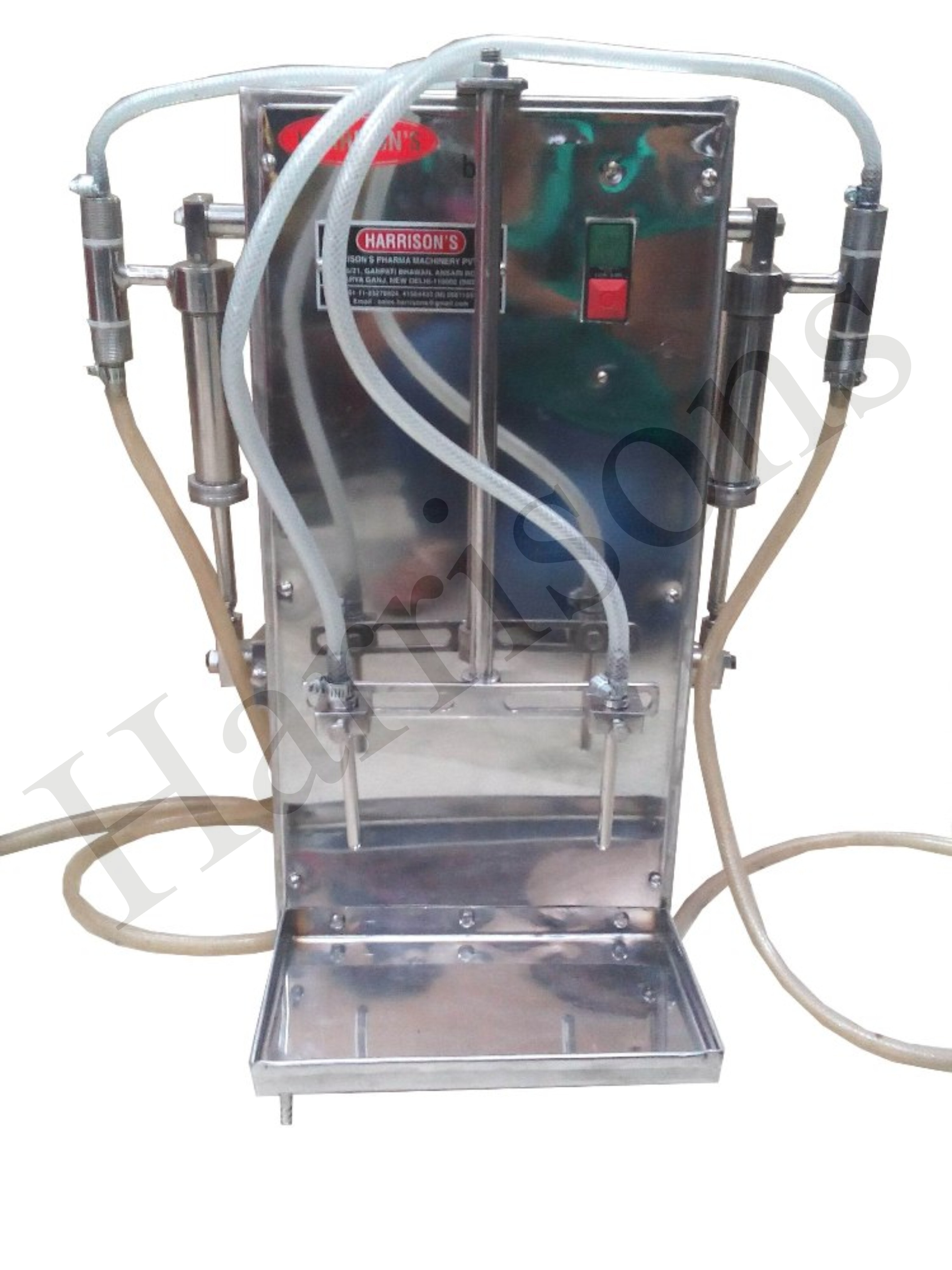

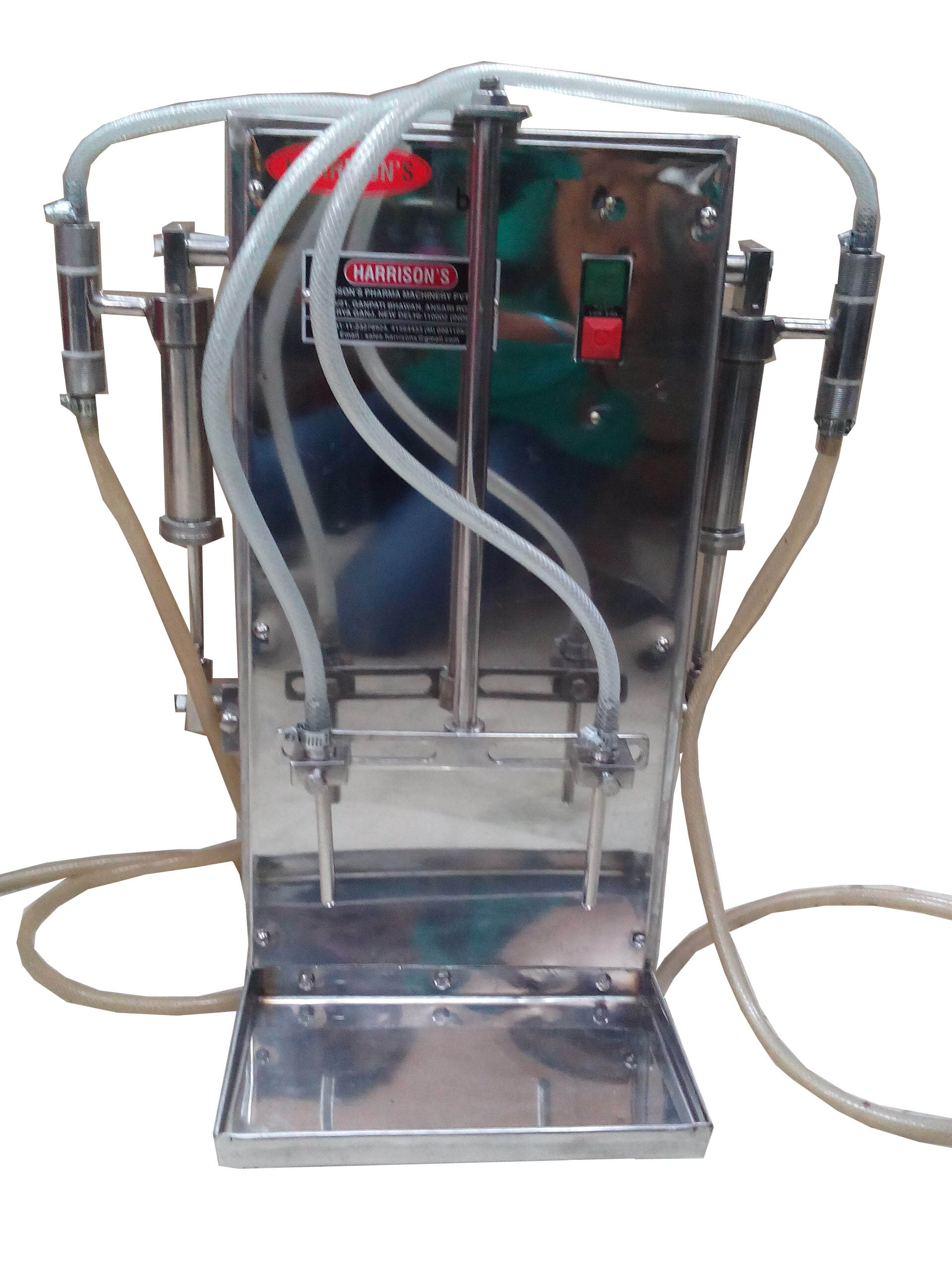

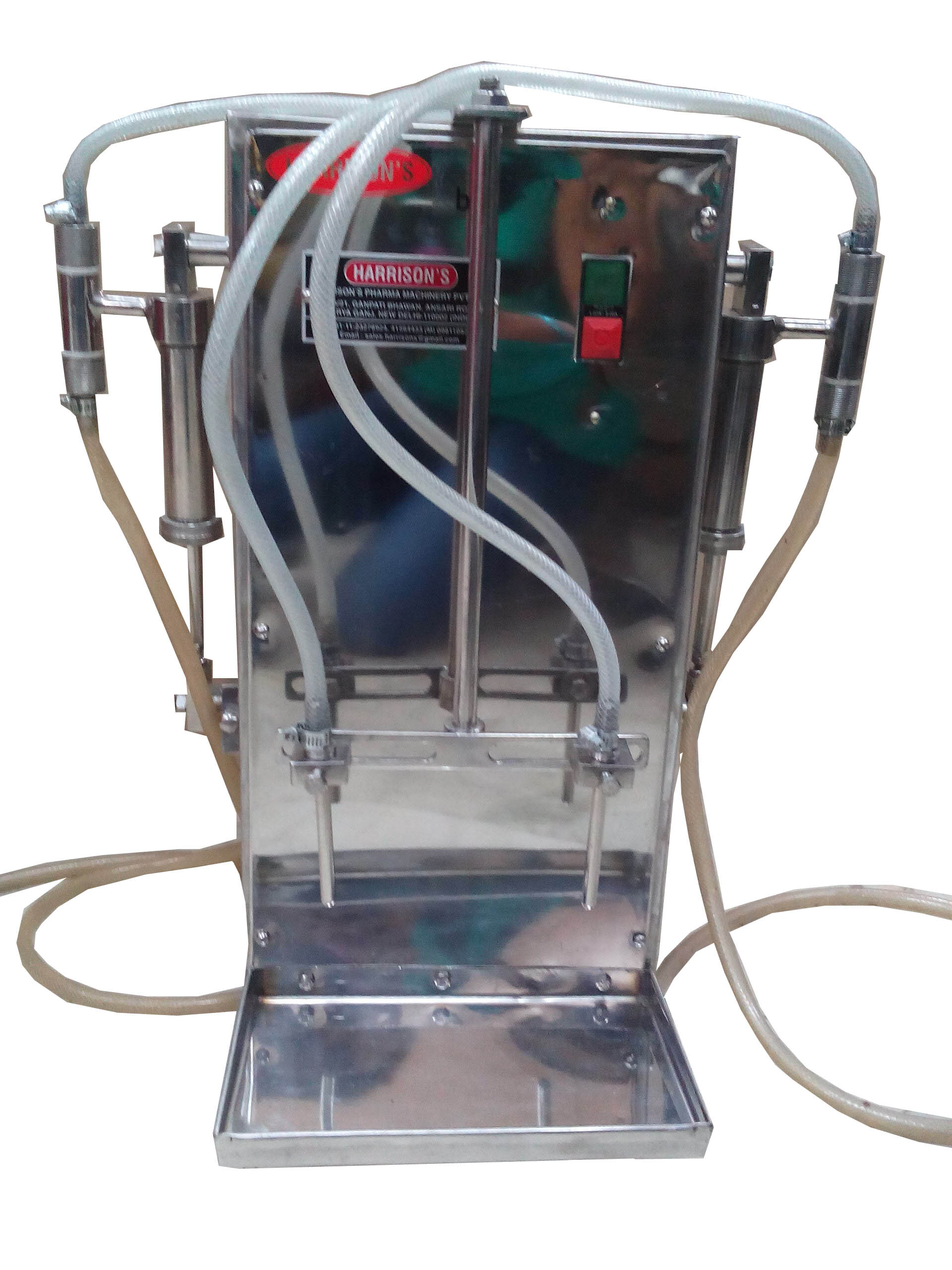

Volumetric Liquid Filling Machine

Price 84500 INR/ Piece

Volumetric Liquid Filling Machine Specification

- Frequency

- 50 Hertz (HZ)

- Usage & Applications

- Industrial

- Material

- Stainless Steel

- Computerized

- No

- Voltage

- 220-440 Volt (v)

- Color

- Silver

- Warranty

- 1 Year

Volumetric Liquid Filling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- South India, Central India, West India

About Volumetric Liquid Filling Machine

We are offering a wide range ofVolumetric LiquidFilling Machine.

Specifications:

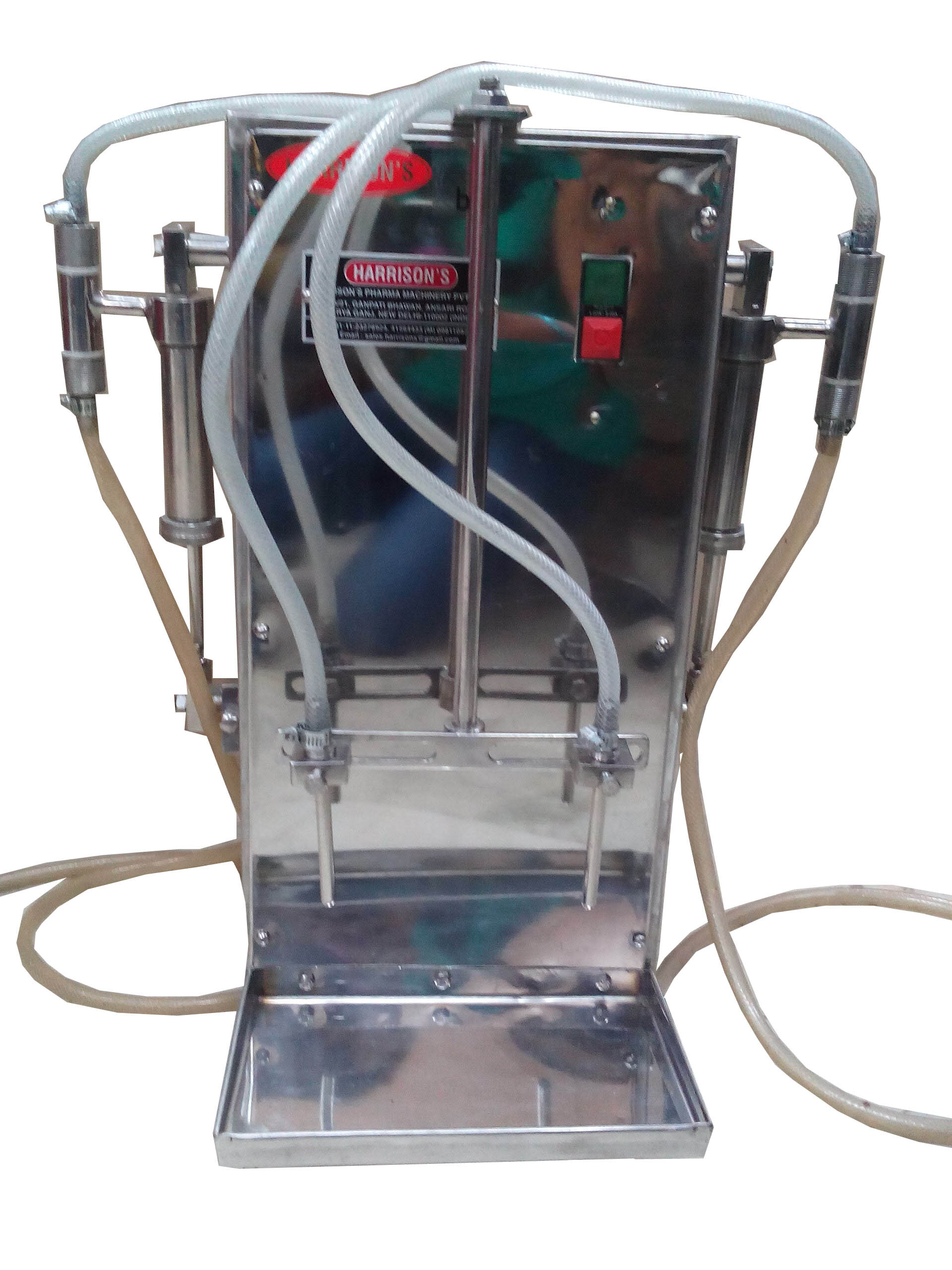

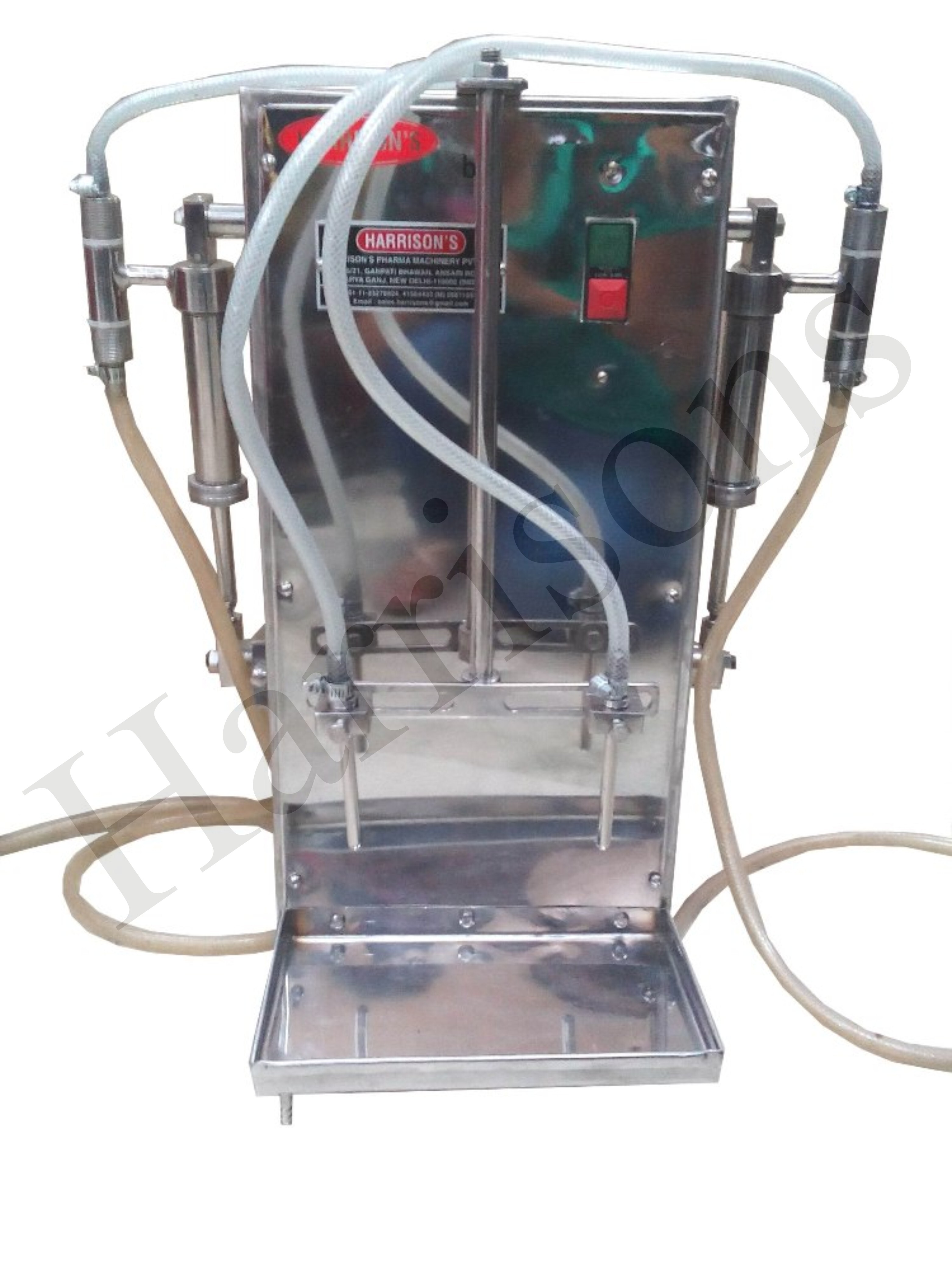

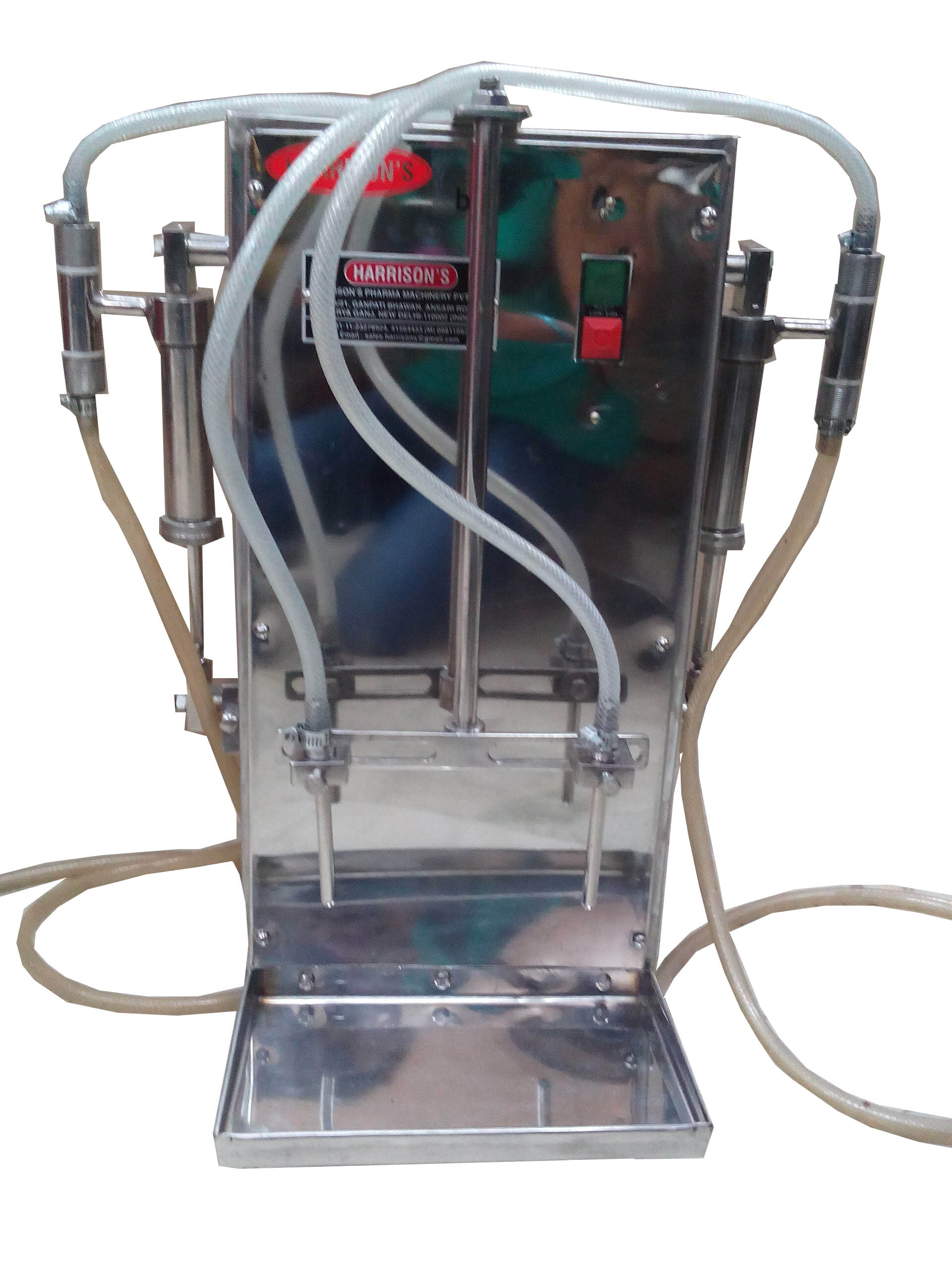

- Standard table model machine

- Complete in all respects with two filling heads and all contact parts of SS-304

- Filling capacity of syringes from 15-125 ml on both sides

- Adjustable nozzle

- 0.5 HP/3 phase elec. motor, starter and suitable reduction gear box

- Quantity adjustment device with filling speed 26-30 bottles per minute/single stroke

- Specification - as above - with filling capacity of syringes from 50 250 ml, on both the sides

- Specification - as above - with filling capacity of syringes on one side 15 125 ml & on the other side 50 250 ml

- Specification - as above - with filling capacity of syringes up to 100 500 ml with 1 HP/ 3 phase elec. motor

Optional features (if required):

- Special long type model of the filling machine mentioned above

- Can be provided with table height adjustment, SS-bottle resting tray

- Provision for adding conveyor to this machine at any later stage

Extra syringes for volumetric filling Machine:

- 3 to 30 ml capacity SS-304 complete syringe

- 15 to 125 ml capacity SS-304 complete syringe

- 90 to 260 ml capacity SS-304 complete syringe.

Specification

| Automatic Grade | Semi-Automatic |

| Driven Type | Electric |

| Material | SS |

| Motor | 0.5 HP to 1 HP |

| Machine Type | Semi-Automatic |

| Capacity | filling capacity of syringes from 50 - 250 ml |

Accurate and Consistent Filling

This volumetric liquid filling machine uses precision mechanics to ensure each container receives an exact volume of liquid, reducing wastage and enhancing product quality. Its robust stainless steel construction provides resistance to corrosion and wear, making it suitable for constant industrial use.

Simple Operation and Maintenance

As the system is not computerized, operators require only minimal training to run the machine efficiently. Regular cleaning and maintenance are facilitated by its smooth, stainless steel surfaces, contributing to consistent performance and machine longevity.

FAQs of Volumetric Liquid Filling Machine:

Q: How does the Volumetric Liquid Filling Machine benefit industrial operations?

A: The machine streamlines liquid packaging by delivering precise volumes, minimizing product loss, and promoting efficient workflow. Its durable stainless steel body ensures longevity and resistance to chemical wear, which is essential for demanding industrial use.Q: What types of liquids can this filling machine handle?

A: Designed for versatility, the machine can fill a wide variety of industrial liquids, provided they are compatible with stainless steel equipment. It is suitable for chemicals, oils, cleaning agents, and other similar products used in industrial manufacturing.Q: When should routine maintenance be performed on the machine?

A: Routine maintenance, such as cleaning the valves and inspecting components, should be conducted at scheduled intervals based on usage frequency, ideally after each production shift or batch, to maintain optimal performance and hygiene.Q: Where is this machine manufactured and supplied from?

A: This volumetric liquid filling machine is manufactured and supplied in India, which ensures local support and efficient delivery within the region for Indian industries.Q: What is the process for filling liquids using this machine?

A: Operators manually set the volume and load containers, after which the machine dispenses the pre-set liquid amount using mechanical volumetric principles. Its non-computerized nature ensures straightforward setup and user-friendly operation.Q: How is the product supported after purchase?

A: The machine comes with a one-year warranty covering manufacturing defects. Customers can contact the manufacturer or supplier in India for warranty support, parts, or service queries during the coverage period.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Liquid Making Machinery Category

Transfer Pump

Price 46500 INR / Piece

Minimum Order Quantity : 2 Pieces

Frequency : 50 Hz Hertz (HZ)

Color : Silver

Warranty : 1 Year

Voltage : 220 V Volt (v)

Filter Press Horizontal

Price 79500 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency : 50 Hertz (HZ)

Color : Silver

Warranty : 1 Year

Voltage : 220440 Volt (v)

Emulsifier / Homogenizer With Lifting System

Price 68500 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency : 50 Hertz (HZ)

Color : Grey

Warranty : 1 Year

Voltage : 220440 Volt (v)

Industrial Motorized Stirrer

Price 107500 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency : 50 Hertz (HZ)

Color : Silver

Warranty : 1 Year

Voltage : 220440 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS