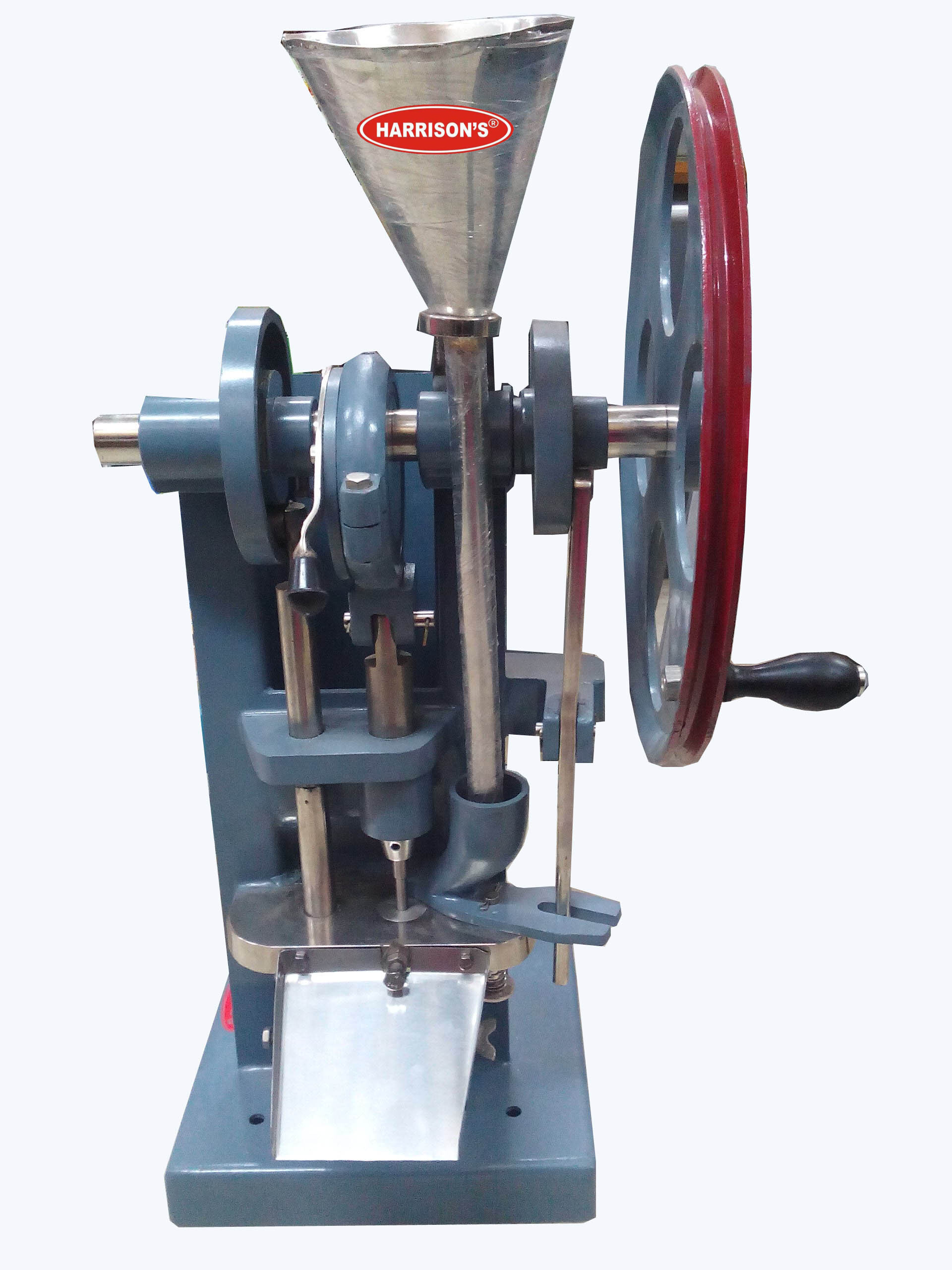

Tablet Making Machine Hand Operated

Price 26500 INR/ Piece

Tablet Making Machine Hand Operated Specification

- Usage & Applications

- Industrial

- Frequency

- 50 Hertz (HZ)

- Computerized

- No

- Control Mode

- Semi-Automatic

- Voltage

- 220-440 Volt (v)

- Color

- Grey

- Warranty

- 1 Year

Tablet Making Machine Hand Operated Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 10 Days

About Tablet Making Machine Hand Operated

Tablet Making Machine Hand Operated

The machine is driven hand operated by circulating wheel. Useful for making tablets upto 100mg and Size of punch & die is 6-8 mm. Automatic compressions and ejection device has been provided, actuated by revolution of the wheel drive. The compression pressure on the tablets, is controlled by adjusting a lever, the powder filled in cavity is controlled automatically by a moving a feeder provided. The machine is supplied without dies / punches. Complete with Hopper,feeder, Tablets slider etc.(without Die & Punch set.)

Specifications

| Brand | Harrison's |

| Automation Grade | Manual |

Efficient and Reliable Tablet Production

This hand-operated tablet making machine offers industrial users a dependable solution for crafting tablets with precision. Its semi-automatic control mode enables users to manage the process effectively without complex electronic systems. The machines robust design and quality materials support consistent output, making it ideal for manufacturers seeking performance and longevity.

Versatility for Industrial Applications

Engineered for industrial usage, this tablet making machine accommodates various production needs. Its compatibility with standard power supplies and simple manual operation makes it suitable for pharmaceutical, chemical, and related sectors. The grey finish and practical build ensure the machine fits seamlessly in diverse factory environments.

FAQs of Tablet Making Machine Hand Operated:

Q: How does the hand-operated tablet making machine function?

A: The machine operates using a semi-automatic control mode where users manually initiate and supervise tablet formation. Electrical power is required for some operations, but no computerized controls are involved, simplifying its use and maintenance.Q: What are the advantages of using this semi-automatic tablet making machine?

A: With its semi-automatic mode, manufacturers benefit from increased control over the tablet-making process and reduced dependency on advanced electronics. Its robust build and 1-year warranty ensure reliable, long-term performance in industrial settings.Q: When should industrial users consider purchasing this machine?

A: Industrial manufacturers or suppliers in need of a straightforward, durable device for tablet production, especially where high-level automation is unnecessary or where manual oversight is preferred, will find this machine particularly suited to their requirements.Q: Where can this tablet making machine be installed and operated?

A: This machine is designed for industrial environments across India. It is compatible with standard voltage (220-440 Volt) and frequency (50 Hertz) requirements, making it adaptable to factories and production units nation-wide.Q: What is the step-by-step process for making tablets using this device?

A: To operate, prepare the tablet material and load it into the machine. The operator manually activates the semi-automatic mechanism, which compresses and shapes the material into tablets, allowing direct supervision for quality control before collection.Q: Who would benefit most from using this tablet making machine?

A: Pharmaceutical manufacturers, chemical producers, and related industrial suppliers seeking dependable tablet production without extensive computerized controls will gain efficiency and flexibility with this hand-operated machine.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tablet Making Machinery Category

Foil Sealer & Tagger Sealing Machine

Price 5800 INR / Piece

Minimum Order Quantity : 5 Pieces

Computerized : No

Color : Red & Black

Warranty : yes

Scoop Stretcher

Price 300 INR / Piece

Minimum Order Quantity : 1 , , Piece

Computerized : No

Color : Silver

Control Mode : Manual

Warranty : 1 Year

Batch Printing Machine - Hand Operated

Price 8500 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Color : Grey

Control Mode : SemiAutomatic

Warranty : 1 Year

Tablet Making Machines

Price 18000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Computerized : Yes

Color : Silver

Control Mode : SemiAutomatic

Warranty : yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS