Double Cone Blender R D Model

Price 78500 INR/ Piece

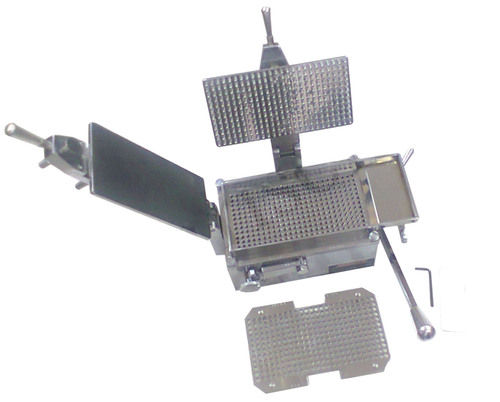

Double Cone Blender R D Model Specification

- Frequency

- 50 Hertz (HZ)

- Usage & Applications

- Industrial

- Material

- Stainless Steel

- Voltage

- 220-440 Volt (v)

- Color

- Silver

- Warranty

- 1 Year

Double Cone Blender R D Model Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- Delivery Time

- 20-30 Days

About Double Cone Blender R D Model

Double Cone Blender - R & D Model that we bring forth for our clients are used extensively for mixing dry powders and granules. These blenders prove beneficial when small portion of one product is mixed with larger portion of another. We manufacture these blenders using stainless steel and these are mounted on mild steel stands.

Some of the other details are as follows:

- Unit is driven by a motor, through a gearbox

- Mixing vessel is fitted with sliding angular blades from inside

- Ensure efficient mixing of powders

- Available in GMP model also

- Cap: 5-20 kg

Specification

| Material | SS |

| Voltage | 220V |

| Design Type | Standard |

| Capacity | 5-20 kg |

Efficient Mixing for Industrial Applications

The Double Cone Blender R&D Model ensures homogenous mixing of dry powders and granules, making it ideal for pharmaceutical, chemical, food, and allied industries. Its gentle tumbling action prevents product degradation while delivering efficient results crucial for research and development protocols.

Reliable and Safe Operation

Featuring a voltage compatibility of 220-440V and a frequency of 50Hz, this blender is engineered to international standards for safety and consistency. Crafted from corrosion-resistant stainless steel with a polished silver finish, it guarantees hygiene and durability even under intensive industrial usage.

FAQs of Double Cone Blender R D Model:

Q: How does the Double Cone Blender R&D Model operate to ensure thorough mixing?

A: The Double Cone Blender works by rotating the mixing chamber, causing the powders or granules to cascade and tumble. This action promotes uniform blending without localized accumulation of material, making it especially effective for delicate or sensitive substances.Q: What are the primary industrial applications of this blender?

A: This model is commonly used in the pharmaceutical, chemical, and food industries, among others, where precise and homogenous mixing of dry powders or granules is essential for research and development, quality testing, and small-scale production.Q: When is it recommended to use a Double Cone Blender instead of other blending equipment?

A: A Double Cone Blender is best suited when gentle yet thorough mixing is required, especially for materials that may be sensitive to shear or degradation. It is ideal for R&D environments where product integrity and uniform composition are critical.Q: Where is this Double Cone Blender typically manufactured and available for supply?

A: This R&D model is manufactured and supplied by reputed companies based in India. These suppliers offer support and service coverage across various regions for industrial users.Q: What is the material construction of the Double Cone Blender and how does it benefit users?

A: The blender is constructed from high-grade stainless steel, which offers excellent resistance to corrosion and contaminants, ensuring that the blending process meets hygiene standards while also prolonging the equipments operational life.Q: How does the warranty coverage benefit industrial users of this equipment?

A: The 1-year warranty offered by the manufacturer provides assurance against manufacturing defects and ensures prompt support, making it a reliable investment for research and development needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in R & D Equipments Category

Tablet Coating Pan - R D Model

Price 70500 INR

Computerized : Yes

Usage & Applications : Used for coating tablets in pharmaceutical and R&D operations

Material : Stainless Steel

Control Mode : Automatic

Hot Air Oven - R D Model

Price 65000 INR

Computerized : Yes

Usage & Applications : Laboratories R&D Units

Material : Stainless Steel

Control Mode : Other, Digital

Ointment Section - R D Purpose

Price 300000 INR

Computerized : Yes

Usage & Applications : Research and Development Ointment Preparation

Material : Stainless Steel

Control Mode : Automatic

Capsule Filling Machine

Price 55000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Usage & Applications : Pharmaceutical industry capsule manufacturing

Material : Stainless Steel

Control Mode : Manual

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS